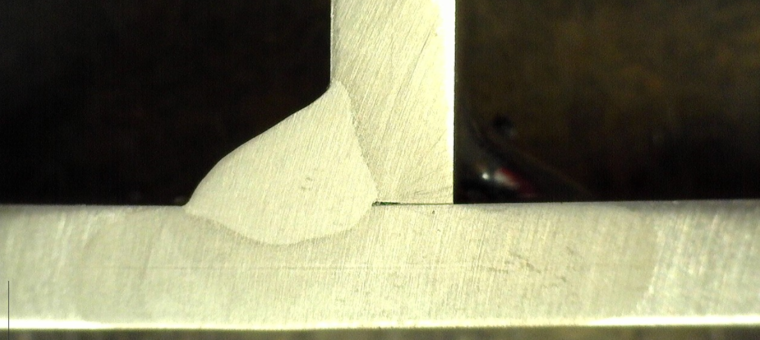

Inspection Before, During and After Welding is Critical

Checklists for the CWI, welder and other production personnel

Weld inspection should not just take place after welding. Inspection before and during welding is critical. But what can you inspect if welding has not been performed? Take a look at the checklists below for pre, during and post weld inspection. Most of these items fall under the responsibility of the welding inspector, but any party involved […]