Category Archives: SAW Process

Which Welding Process Produces the Strongest Welds

SMAW, GTAW, GMAW, FCAW, MCAW or SAW?

The Importance of Weld Repair Procedures

A repair procedure is necessary any time there is a defect in welding that must be corrected. The repair procedure is not just a welding procedure specification, but rather a set of instructions and rules on how to repair different types of defects. There is no standard format for a repair procedure, or a standard […]

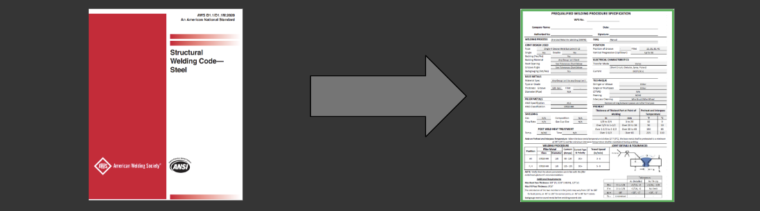

AWS D1.1 Prequalified Welding Procedures

Prequalified WPSs for GMAW, MCAW, SMAW, FCAW & FCAW-S

Prequalified welding procedures must adhere to the strict requiremnts of the welding codes which permit their use. AWS D1.1 Structural Welding Code (Steel) is one that allows their use. Prequalified WPSs are exempt from testing becasue there is reasonable assurance that as long as all the requirements are met the deposited weld will be sound […]

Causes of Porosity in Submerged Arc Welds

Submerged arc welding is typically done automatically, meaning it is not done by hand, but rather set up as hard automation. The operator simply controls the welding machine and torch position to obtain the desired results. Typically,the system is run by an operator, not a welder. So when problems come up, the operator may not […]