AWS D1.6 is the Structural Welding Code for Stainless Steel. Its primary concern is with the structural integrity of weldments and not with resistance to corrosion, creep or sensitization. As a matter of fact, the word “corrosion” appears only eight times in the 9 clauses of AWS D1.6. Requirements for these concerns are the responsibility of the engineer in charge or contractor. The code does provide useful information in regards to the use of adequate filler metals that match not only the strength of the base metal but also its resistance to corrosion and creep. However, this in no way guarantees suitability for all corrosion environments.

AWS D1.6 Structural Welding Code (Stainless Steel) covers mainly austenitic stainless steels and focuses on structural integrity rather than resistance to corrosion.

AWS D1.6, like AWS D1.1 (Steel) allows for the use of prequalified welding procedure specifications (PWSPs). This is advantageous because it can save fabricators a lot of time and money by providing an exemption from qualification by testing in accordance with Clause 6 – Qualification.

The prequalification of WPSs follows very similar guidelines and limitations as those of prequalified WPSs for carbon steel as detailed in AWS D1.1. The steps for prequalification of WPSs for structural stainless steel are as follows:

- Use a prequalified welding process – these processes include SMAW, GTAW, GMAW and FCAW. SAW is not a prequalified welding process. This may seem strange as it is when dealing with carbon steel. However, the reason for not being a prequalified process in AWS D1.6 is because fluxes for Stainless Steels are not presently classified by AWS.

- Use an approved base metal – select a base metal from Table 2 of AWS D1.6.

- Use an approved filler metal – refer to Table 5.3 to choose an approved matching filler metal

- Follow preheat and interpass temperature requirements – in general, structural stainless steels do not require preheat other than to remove moisture from the work pieces. Interpass temperature should not exceed 350˚F [175˚C].

- Stay within the limits outlined in Table 5.1 and 5.4 – these limits are for variables such as amperage, voltage, travel speed, shielding gas composition and flow rate, position of welding, and filler metal classification and size. Also, limits on root pass thickness, fill pass thickness, fillet weld size and layer width are specified.

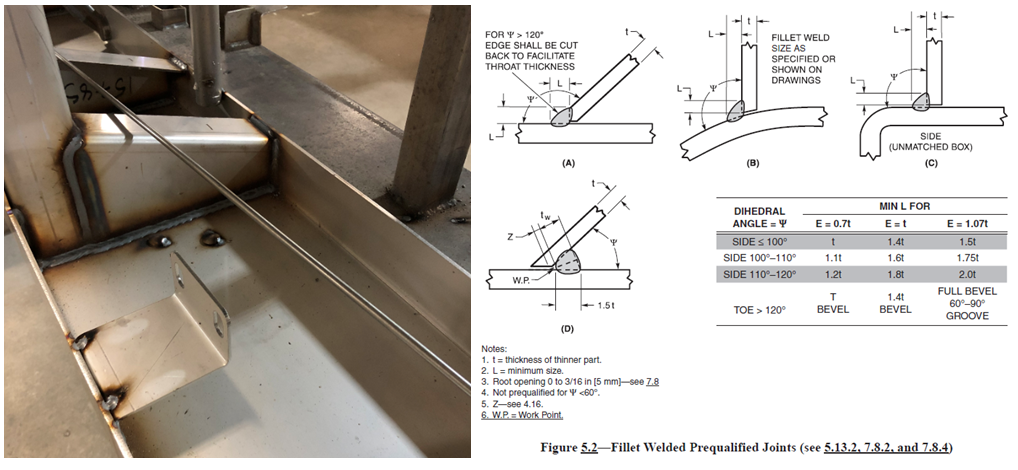

- Use a prequalified joint – detailed in Figure 5.2 through 5.5 are prequalified joints that shall be used with PWPSs

AWS D1.6 contains the complete list of prequalified joints. Tolerances are provided. In order to use a prequalified welding procedure the dimensional limitations of the prequalified joints must be met.

Three things worth noting:

- If you are required to qualify procedures and welders to AWS D1.6 you must have a copy of this code. This can be purchased through the AWS website. Even if you have a consultant help you with the qualifications, AWS D1.6 still spells out a lot of fabrication, design and inspection requirements that you must know.

- You DO NOT need to be a CWI or welding engineer to qualify welders and procedures. You simply need an understanding of the requirements set forth by the code. CWIs are usually the ones doing the qualifications because they have received the training for it.

- The use of prequalified WPSs can be advantageous, but it also has some potential drawbacks. These drawbacks are the same whether you are welding stainless, aluminum or mild steel. To earn about the some of these areas of concern you can read Dangers of Using Prequalified Welding Procedures.

In our next article we’ll cover the requirements of AWS D1.6 for qualification of WPSs by testing. You will see then that the destructive tests are all for assuring structural integrity and not resistance to corrosion.

As stated above, the welding engineer or engineer in charge is responsible for adding, deleting or otherwise modifying the requirement of AWS D1.6 Structural Welding Code (Stainless Steel) in order to meet particular requirements of a specific structure. This may relate to extremely corrosive environments such as those for subsea structures or those exposed to sour gas. When base metals not covered under this codes, such as AL6XN (super austenitic stainless steel) are used, qualification by testing is required. The welding engineer must in this case complement the requirement of the code. Any requirements beyond the scope of AWS D1.6 must be detailed in contract document or approved by the engineer in charge.

Reference: AWS D1.6/D1.6M:2017 Structural Welding Code – Stainless Steel

Please note: I reserve the right to delete comments that are offensive or off-topic.