One of the dangers we should be aware of when welding high strength steels or even thick sections of low carbon steel is hydrogen induced cracking. Hydrogen induced cracking, also called hydrogen assisted cracking and cold cracking, is caused when three conditions are present. First, we need a susceptible microstructure (base material related). Second, we need a high level of restraint (design related). And third, we need a threshold level of hydrogen (fabrication related). Most often we can’t do anything about the first two, but we can always ensure we follow low hydrogen welding practices.

This starts with the use of low hydrogen electrodes. It is important to know that a low hydrogen electrode is only “low hydrogen” if it is used and kept (stored) properly.

Low hydrogen SMAW (stick) electrodes come in hermetically sealed cans to prevent moisture pick up. However, once the package is open the coating will begin to pick up moisture from the atmosphere and reach levels of hydrogen above permissible limits within a few hours. The rate of moisture pickup depends on several factors including, but not limited to relative humidity, electrode coating characteristics, and storage locations.

Once low hydrogen electrode hermetically sealed cans have been opened and the electrodes exposed to the atmosphere, they should be used within a few hours. If not, they should be stored in a holding oven. AWS D1.1 Structural Welding Code (Steel) suggests that these electrodes should be store at a temperature of 250F to 300F. It is common practice to have welders received enough low hydrogen electrodes to last them about half a shift. This is good practice as it minimizes the risk of excessive moisture pick up.

Rod ovens for low hydrogen electrodes are readily available. There are also portable rod ovens which can hold up to 5 pounds of electrodes which welders can carry to their stations or anywhere on a job site.

There are several reasons why you want to keep the moisture level below the maximum limit. The main four are:

- High levels of moisture can cause porosity. It may not be enough to have surface porosity, but an x-ray will reveal internal porosity when used.

- Excessive moisture can affect the operating characteristics of the electrode

- The weld is susceptible to hydrogen induced cracking.

- Low levels of hydrogen improve low temperature toughness

Low hydrogen electrodes with the “R” designation(i.e. E7018-H4R) have been tested to determine the moisture content of the electrode after 9 hours of exposure. After this time the electrode still maintains a level that is permissible. After 9 hours however, the electrodes must be returned to the oven for storage.

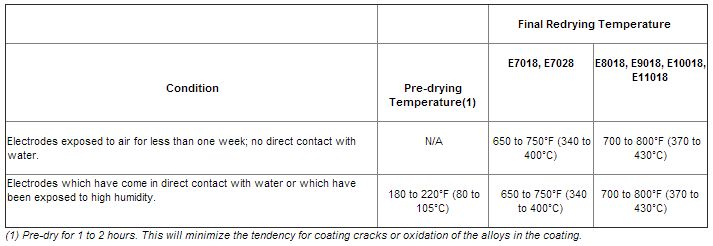

If you have low hydrogen electrodes that have been exposed to the environment for greater than 9 hours you must follow a process to redry them. Follow the table below for instruction on temperatures and times.

Source: Fabricators’ and Erectors’ Guide to Welded Steel Construction

This is very helpful for me.

We are glad you find this helpful. Thanks for reading!