If you have ever been tasked with selecting the right specification and grade of steel for a particular application you know there are hundreds of choices. Typically these are based on the materials tensile strength and yield strength. There are many factors that go into selecting the right base metal for a given application. In some cases we want high strength as is the case semi-trailer frames. This is advantageous because it reduces the weight of the vehicle by requiring a lesser cross sectional area than if using a lower strength steel to handle the same amount of stress. In other cases we want a lower strength steel that is more ductile and can absorb more energy before fracturing, as may be the case in some steel bridges.

Tensile strength, yield strength and ductility are mechanical properties of steel. Another mechanical property is fracture toughness, or commonly referred to simply as ‘toughness.’ In some cases the terms toughness and strength are used interchangeably, but this in incorrect. It is assumed that the stronger the material the tougher it is. This stems from a lack of understanding between strength and toughness.

To distinguish between the two lets first look at some basic definitions.

Yield Strength – measure of the stress a metal can support before deforming.

Tensile Strength – measure of the maximum stress that a metal can support before fracture begins.

Fracture Toughness – the ability of a metal to absorb energy in the presence of a sharp notch, often when subjected to an impact load.

For several applications we probably want these three to be as high as possible. There are certain design considerations why we may want the yield strength to be quite a bit lower than the tensile strength, but in general the higher the strength the better. And based on the definitions above we certainly want high fracture toughness in the event that a crack develops or if inspection missed other stress risers such as undercut, overlap or incomplete penetration.

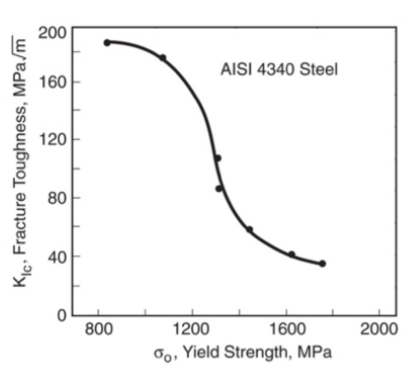

However, there is a problem in trying to achieve high values for all. For the base metals and filler metals used in steel construction there is an inverse relationship between strength and toughness. As strength goes up toughness goes down and vice versa. The chart below illustrates this relationship.

Because strength (yield and tensile) is inversely related to toughness we need to find a good balance when designing structures that require a minimum amount of fracture toughness. A perfect example is that of a bridge. Bridges endure a very harsh environment ranging from cyclic loads due to vehicles, wind and water currents to extreme cold temperatures to corrosive environments.

It is almost a certainty that all steel bridges will develop cracks. Because of this, we want high fracture toughness in order to increase the time between crack initiation and brittle fracture which could potentially be catastrophic. This is the same as decreasing the crack’s growth rate. This is very important in bridges because inspections are done at certain time intervals. So you don’t want a crack to develop between inspections and propagate to the point of fracture.

Bridges endure harsh environments which accelerate crack initiation. Good toughness prevents this crack from propagating too quickly and leading to fracture.

A thorough understanding of the toughness of the base metal, weld metal and heat affected zone allow inspectors and engineers to determine if a crack on a bridge needs to be repaired or if it can be left alone for some time. Repairs are extremely costly. So if it is known that it will take a crack 5 years to reach a critical size, the determination to wait may be acceptable. But why wait to repair a crack? In some cases it is best to do many repairs at once. So instead of repairing cracks on a bridge throughout the year, you do it once a repair is critical and take care of all cracks and other defects at that time. This way, interruption to traffic is minimized and costs are significantly reduce. All this while still guaranteeing the structural integrity of the bridge.

So if we know that high toughness is critical we will pick a material that has very low strength, right? Maybe not. If you go with lower strength steels you lose the stiffness and strength required for some designs causing you to need a lot more steel. This can be more support beams, thicker sections, etc. Using low-strength steel to benefit from higher toughness can mean significant costs in the manufacturing process. So, as you can see there is a delicate balance between the two.

The welding process can significantly change the toughness of a base metal. Because of this, codes such as the AWS D1.5 Bridge Code require CVN (charpy v-notch) testing of welding procedures. CVN testing provides values for toughness. Manufacturers of filler metals are required to do this testing when manufacturing consumables that are used in applications requiring minimum values of toughness. The contractor (fabricator) is then required to qualify welding procedures by testing which also includes CVN tests.

Please note: I reserve the right to delete comments that are offensive or off-topic.