One of the most common requests for help that we get pertains to the qualification of welders. Our customers win a contract and later find out they need to qualify their welders. Often, they realize this right before production is to begin and scramble to get their qualifications done. Even worse, they may also need to qualify welding procedures if the use of prequalified welding procedures is not allowed by contract documents. They enter panic mode and look for the easiest and fastest way to get this done.

There is nothing wrong with getting these qualifications done as quickly as possible, but proper procedures must be followed. First and foremost, study the contract documents (also referred to as referencing documents). These are provided by the customer for which you are doing the work. These documents should specify which code or standard you must follow for the qualification of your welding procedures and welders. Codes such as AWS D1.1, D1.2, D1.6, API 1104 or ASME Section IX may be called. If there is no specified code or standard you have two good choices:

- Pick a code that covers the material types and thickness ranges you will be using

- Use AWS specification B2.1/B2.1M (Specification for Welding Procedure and Performance Qualification)

Once you have a code, standard or specification to follow simply refer to the clause that details welder performance qualification. There is a misconception that only a certified welding inspector (CWI) or a welding engineer can oversee the qualification tests. Another misconception is that it needs to be done by a third party. This may be the case if specified in the contract documents, but if it’s not you can have one of your own employees do this. It is important that this person be competent in welding and has thoroughly reviewed and understands the code or standard being used.

Many codes allow for the qualification tests to be administerd by any individual. Knowleddge of welding and the code being used is necessary, but no special qualifications such as being a welding engineer or CWI are needed.

Another misconception is that once a welder is qualified by testing he or she is qualified to weld on anything (any material, any thickness, and/or any position). This is not the case. A welder’s qualification is limited to several variables including: welding process, welding position, material type (group), material thickness and joint type. A welder qualified to weld with GMAW in the flat (1F) position is certainly not qualified to weld on pipe, even in the flat position.

If you must outsource the qualification of your welders make sure you have the following information as a minimum before calling a third party:

- Code, standard or specification that must be followed

- Information on material(s) to be welded

- Type/Chemistry

- Thickness range

- Welding positions to be used in production

- Welding process to be used

The details of the performance qualification tests depend on the information above. There are tests that can qualify a welder for different positions, different materials and different thicknesses. Someone that is well-versed in the code or standards being followed can save you a lot of money in qualification tests by doing the least number of tests to qualify your welder for everything he will be welding.

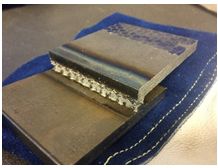

Once the test is completed the acceptance criteria specified by the code or standard must be met. This typically includes visual examination (VT). VT looks or surface flaws such as porosity, cracks, undercut, overlap, weld size and several others and compares these discontinuities to acceptable limits. If the weld test passes VT, it then goes to destructive testing. This will typically include cross section etches and break tests for fillet welds or bend tests (side, root, face) for groove welds.

A fillet break tests lets you know if root fusion was achieved throught the entire length of the joint.

If these destructive tests meet acceptance criteria the welder is qualified. Everything must be recorded. A welder performance qualification record (WPQR) must be kept on file. These qualifications may expire per the code or standard being followed, so make sure you understand these requirements.

Reference: Qualification of Welding Procedures, Welders and Welding Operators per AWS D1.1 (2017)

Do you want more information on how you can perform your own qualifications?

Do you want more information on how you can perform your own qualifications?

“Qualifying Welding Procedures, Welders and Welding Operators” is a guide developed to help you peform your own qualifications in full compliance to AWS D1.1 Structural Welding Code.

Greetings,

Iam working with big company which is deal with welding in most of projects activities.

Regarding your subject and my interesting, I am looking for a new technology it will support to qualifying a new welder .

If you have we can do business together.

Hello Mohammed. Please feel free to send us more information via email. Looking forward to it!

Nice it will add to knowledge of engineer at one desk. Useful information.

Thanks Manoj. Happy you found this helpful.

Thank you for this brilliant information on qualifications.