Tag Archives: welding procedure specification

7 Things to Consider When Choosing the Best Welding Process for your Welding Procedure

Selecting the best welding process is a critical step in developing a welding procedure that attains the desired quality and optimizes productivity. Many times we look for the welding process that can give us the highest deposition rate to optimize productivity. However, every welding process has limitations. For example, submerged arc welding (SAW) has extremely […]

How to get a Qualified Welding Procedure Quickly

Have you ever been in a situation in which you need a qualified welding procedure immediately? Maybe you just failed an audit and have to halt production until a valid welding procedure is provided. Or maybe you’re just in a hurry to get started with a new job. Regardless of the reason you need the […]

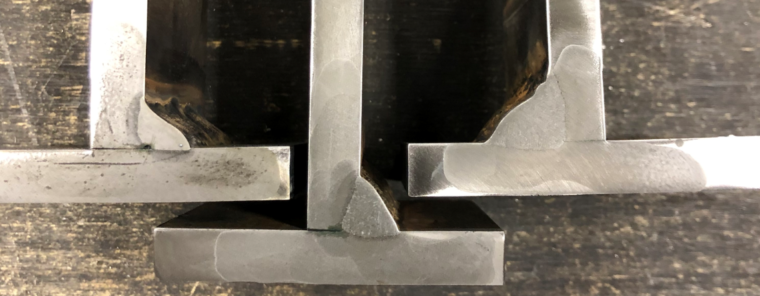

Importance of Weld Failure Analysis

Basic guidelines to troubleshoot weld failures

21 Changes to PQR Essential Variables that Require WPS Requalification

Have you ever seen a welding procedure specification with established amperage ranging from 200 to 550 amps? Or voltage ranging from 21 to 29 volts? Or some other variable with a huge window? This is all too common, but extremely dangerous. Why? Because changes to essential variables beyond that which is reasonable will affect the […]

Why prequalified welding procedures are exempt from testing

One of the advantages of using prequalified welding procedures is that you can save a lot of time and money because they are exempt from testing. This means you don’t need to perform any destructive or nondestructive testing. You simply follow the requirements of AWS D1.1 and you can write a prequalified welding procedure and […]

How to Develop a Welding Procedure Specification

Developing, or writing a welding procedure, goes far beyond setting up amps and volts. It entails the selection of many variables which fall under the 9 required components of welding procedure specifications we discussed last week. Today we look at those 9 components again, but rather than just stating what they contain we explain how […]

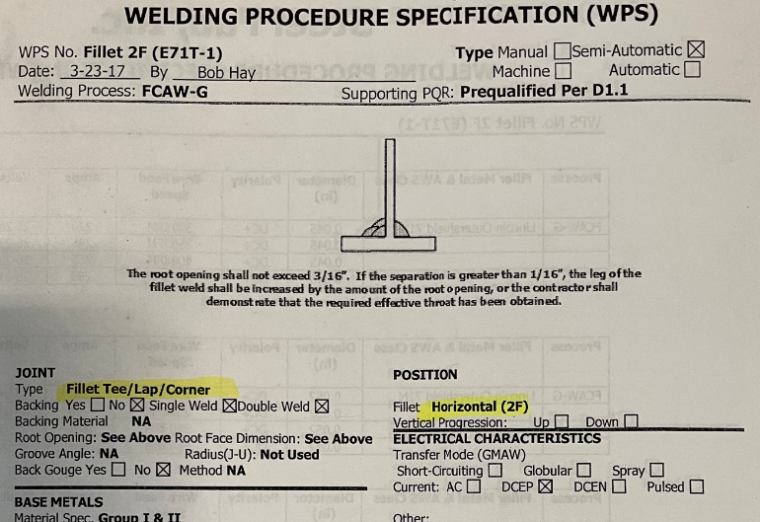

9 Required Components of Welding Procedure Specifications

Regardless what position you hold, if you work in the welding industry you have heard of welding procedures specifications (WPSs). To some, a welding procedure simply means the selection of a few variables such as amps and volts. To others, these are the documents that govern all welding done in their facility. A […]

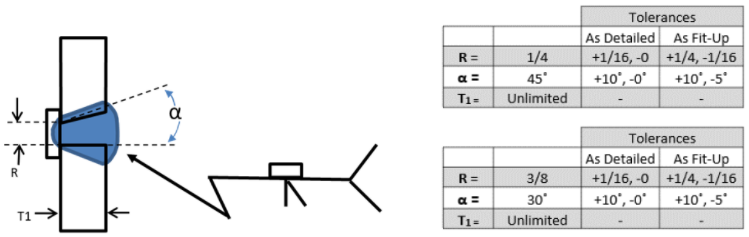

FCAW prequalified welding procedures and their limitations

Dangers even if you follow all the requirements of AWS D1.1

The use of prequalified welding procedures has many advantages as well as many disadvantages. One danger of using prequalified welding procedures is that AWS D1.1 allows for quite a bit of freedom in weld sizes. If you look at Table 5.1 –Prequalified WPS Requirements of AWS D1.1/D1.1M:2020 Structural Welding Code (Steel) you’ll see that in […]

Basic (Overlooked) Steps to Develop a Welding Procedure

A welding procedure specification (WPS) consists of a series of welding variables and corresponding allowable ranges. The selection of these ranges is very important. The idea is that if the welder is within all acceptable ranges he or she will deposit a sound weld, provided of course that the welder has the required skill. The […]