This is a question that is often asked. The short and quick answer is: they are all the same. However, to understand why that is let’s take a quick look at the three elements that determine the strength of a weld:

- Weld length

- Weld size

- Weld (filler) metal strength

Since we are trying to compare processes we would need to keep all other variables the same. So if we make welds of the same length, the same size and using the same strength filler metal every welding process will produce the exact same weld strength.

A ¼” tig (GTAW) fillet weld using ER70S-2 filler metal will have the same strength as a ¼” submerged arc (SAW) weld using an EM12K filler metal. One thing that needs to also stay the same is depth of penetration when welding fillet welds and partial joint penetration welds. More on this below.

Welds made with different welding processes will always have the same strength it they are complete joint penetration (CJP) welds, if they are of the same length and if they use filler metals having equivalent minimum tensile strengths. In this case, regardless of process there is no more or no less penetration. So the effective weld area (weld size) is the exact whether you welded with stick (SMAW), tig (GTAW), flux-core (FCAW) or any other process.

Complete joint penetration (CJP) welds will have the exact same effective weld size regardless of welding process.

There are some that will argue, and rightly so, that welding processes with differnt heat inputs will produce welds with different strength and ductility levels. The reasoning behind this is that if we have very high heat input we’ll have a slower cooling rate than if we use a very low heat input process. However, this is true in carbon steels and not necessarily in other materials. This is also beyond the scope of the simple question with which we started this article.

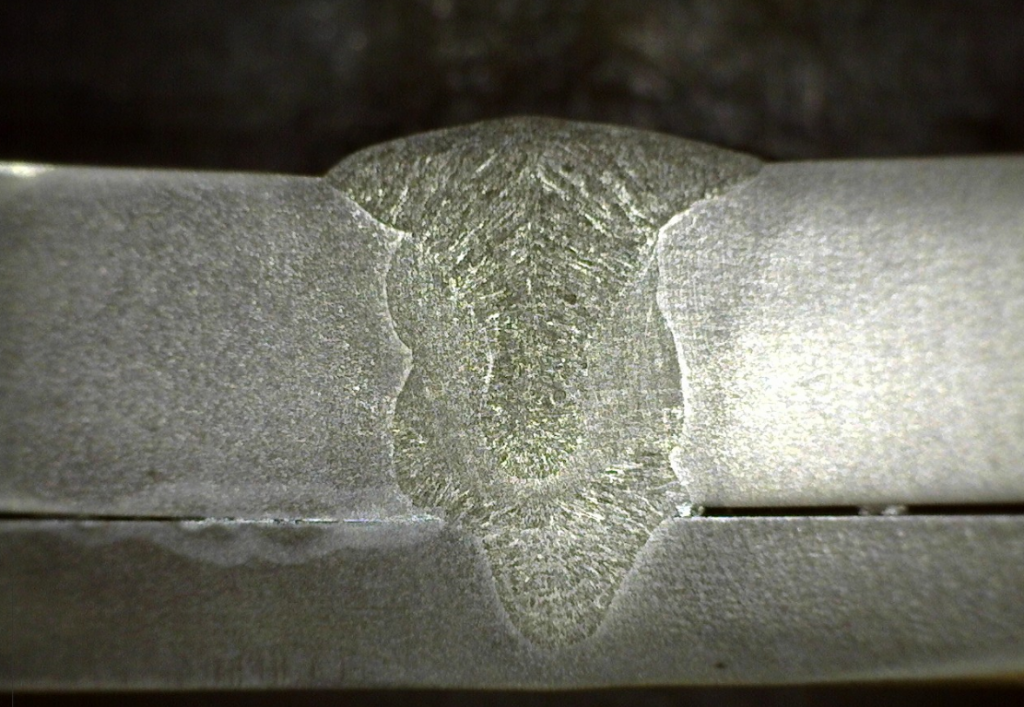

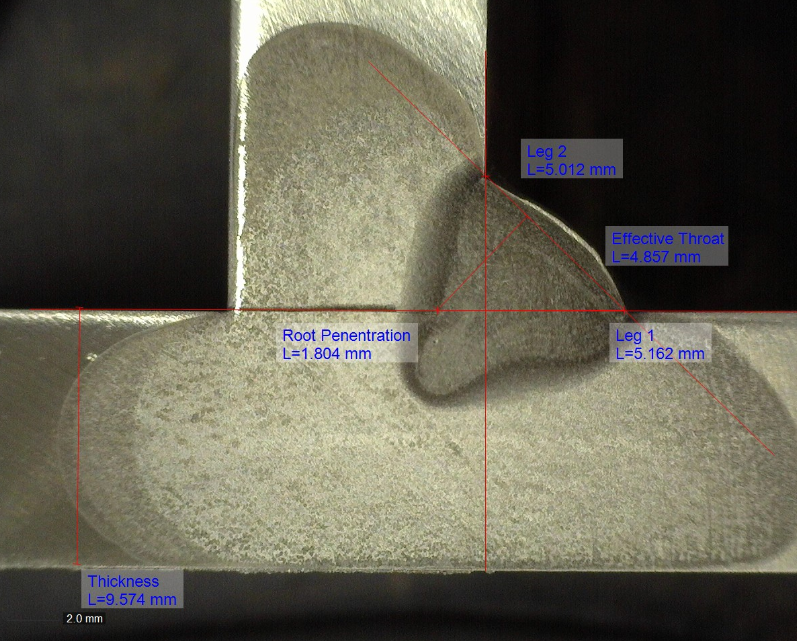

Where we can see a difference in the strength of weld between different welding processes is in partial joint penetration (PJP) welds and fillet welds. Why? Because in these cases depth of root penetration matters. The deeper we penetrate into the root the larger our weld size (for PJPs) and the larger our effective throat (for fillet welds).

Penetration beyond the root increases the load carrying capacity of a fillet weld because it increases the effective throat and consequently the effective weld area.

For a detailed explanation of why deeper penetration on fillet welds and PJPs matter read Bigger Is Not Always Better and Importance of Root Fusion.

Going back to the ¼” fillet welds made with GTAW and SAW. In reality, a GTAW weld has very shallow penetration. In the case of a fillet weld you can easily achieve root fusion but will hardly have any penetration beyond the root. On the other hand, with SAW you will typically see very deep penetration. The deeper the penetration into the root of a fillet weld the larger the dimension of the effective throat and the higher the load carrying capacity (strength) of the weld.

So for PJP welds and fillet welds, if you are looking to get the maximum strength out of your welds (and staying within the weld size and length specified in the print) aim for the deepest penetration possible. SAW is the process with the deepest penetration and GTAW typically has the shallowest penetration followed by SMAW. GMAW, FCAW and MCAW all have roughly the same capabilities.

This is an interesting topic, but typically if we need to increase the strength of a weld we don’t focus so much on welding process but on the three variables mentioned above: weld length, weld size and filler metal strength.

Reference: Welding Procedure Development for Non Welding Engineers

There are several variable factors that affect the joint strength like strength of welding electrode or filler metal, design of joint, and type joint. If we consider all above mentions are constant or same then GTAW can give strongest joint.

Reason: – GTAW has only 10-15 % dilution, low dilution will provide highest strength and GTAW also having High Arc temperature that is around 10000C that is very high heat input (consider same size of filler metal or electrode). If heat input is high we shall have slower cooling rate. This produces higher ductility and higher tensile strength.

Excellent point. THanks for sharing. However, high heat input and slower cooling rate will typically reduce strength on carbon steels. They do increase ductility and fracture toughness though.