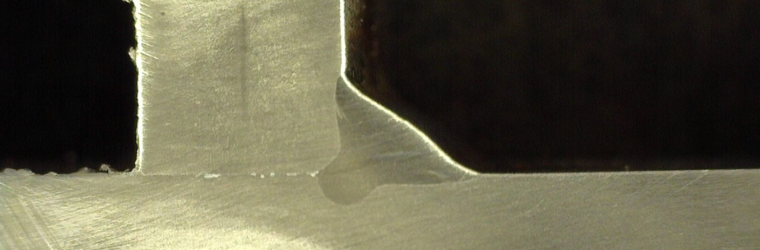

The qualification of welders and welding procedures often involves macro-examination of welds. Performing macro-etches is a relatively simple procedure, but strict guidelines must be followed to ensure safety. Most chemicals used in etching solutions are hazardous and must be handled accordingly. Any person etching with these chemicals must familiarize him or herself with the corresponding Safety Data Sheet (SDS).

We received many inquiries from our readers that are following our guide, Qualification of Welding Procedures and Welders for their qualifications asking about etching solutions. The scope of the above-mentioned publication was structural steel, but its principles can be followed for other materials. This article goes beyond just steel and looks at etching for other metals such as aluminum, copper alloys and stainless steel.

Different alloys require different etching solutions. If you work with many alloys you will need to have several chemicals available. It is imperative that you have SOPs in place that thoroughly explain handling procedures as well as mixing procedures. Do not attempt to mix any of these chemicals without proper training.

Carbon and Low-Alloy Steels

Three acids will work to etch low carbon steel: nitric acid, ammonium persulfate, and iodide/potassium iodide. Mix as follows.

- Nitric Acid – mixture of 5 – 10% nitric acid with the balance being alcohol. Water will work, but alcohol is preferred. Use at room temperature.

- Ammonium Persulfate – Mix one part ammonium persulfate to nine parts water by weight. Use at room temperature. Apply with a cotton swab.

- Iodide and Potassium Iodide – Mix one part iodide, two parts potassium iodide and ten parts water by weight. Apply with a brush at room temperature.

Stainless Steel

For stainless steels stick with the following mixture. Apply at room temperature with a cotton swab or immerse the part in the solution.

- 200g ferric chloride (FeCl3) + 300mL nitric acid (HNO3) + 100mL water (H20)

- Quick alternative: Printed Circuit (PC) Board etchant containing Ferric Chloride – apply to specimen when warm and flush quickly

Aluminum Alloys

The solution that works for aluminum is also a three part mixture composed of the following. It should be used at room temperature.

- 15mL hydrochloric acid + 10mL hydrofluoric acid + 85mL water

Copper Alloys

For copper and copper alloys use concentrated nitric acid. Immerse the specimen in concentrated nitric acid for 30 – 45 seconds. Then rinse with water. After a thorough rinse, immerse in a mixture of 50% nitric acid/50% water. Rinse again and remove the white residue with alcohol or water.

Nickel Alloys

A solution that works well for nickel alloys is a three part mixture that should be used fresh every time. The specimen must be immersed in this solution for 1 – 2 minutes. The mix consists of:

- 1 part hydrogen peroxide (H2O2) + 2 parts hydrochloric (HCl) acid + 3 parts water (H20)

Titanium Alloys

For titanium use the following mixture at room temperature by immersing the specimen or applying the solution by swabbing.

- 3mL hydrofluoric acid + 6mL nitric acid + 90mL water

Remember to follow safety rules when handling these solutions. Always examine safety data sheets (SDS) to understand the risks and the remedies should problems occur. Always use these acids and solutions in a well-ventilated area and with quick access to water for a thorough rinse (eye and full body). When not in use these solutions must be capped, stored and locked in a secure location.

References: The Procedure Handbook for Arc Welding

Qualification of Welding Procedures, Welders and Welding Operators

AWS B2.1/B2.1M:2014- Specification for Welding Procedure and Performance Qualification

Please Quote for etching solutions for weld joints on steel / Ferrous metals