Category Archives: Weld Failure

Troubleshooting Welding Burn-through

Burn-through is a common defect in welding of light gauge materials. It is typically results in costly scrapping of parts since it can be difficult to fix. Or, if left in place when there are not structural integrity concerns it looks awful and portrays extremely poor quality. The following is an excerpt from our guide: […]

The Challenges of Welding in Cold Temperatures

Welding in cold temperatures poses two critical challenges. First, the brutal conditions welders must endure and second, the performance of steel structures in cold temperatures. Many times we forget about the former by focusing too much on the latter. If you ever get a chance to talk to welders that have welded in both extreme […]

Demystifying Fatigue Fractures in Welding: The 3 Stages of Fatigue Fracture

In today’s article we’ll be discussing a critical aspect of welding which is crucial in ensuring the safety and long useful life of structures. When engineers conduct a fitness for service analysis of structures they are looking for flaws. These flaws may be cracks, loose bolts, deformations, rust damage (thinning of structural members) and other […]

4 Types of Loading in Welded Structures

There are four types of loading experienced by welds and welded structures. These types of loading are a function of the strain rate (the rate at which deformation occurs in a material due to an applied load) and the number of loading cycles experienced by the welded member. The 4 types of loading are: Static […]

Why Welds Fail: It’s never just one thing

Weld failures happen all the time. Some are more serious than others in terms of cost and potential for property damage and bodily harm. If a weld failure is considered serious it typically gets a lot of attention. Forensics labs and industry experts get called to determine the root cause of the failure. It may […]

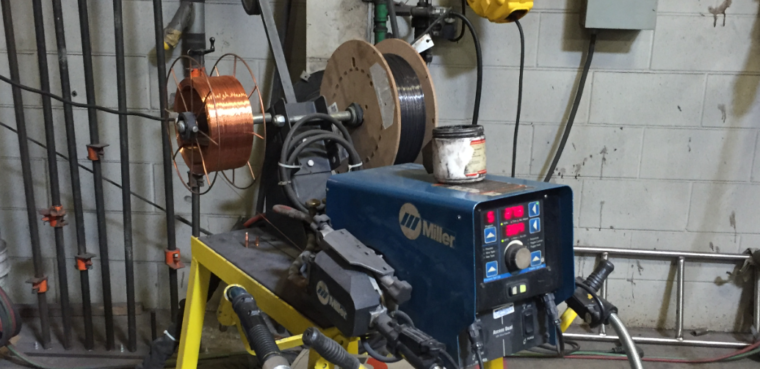

How to Troubleshoot Bad Welds and Other Welding Problems

If you own, run or work at a welding facility you have undoubtfully had to troubleshoot bad welds. Troubleshooting is necessary in order to solve problems, but if you do not have a clear methodology or process for troubleshooting it can be a huge source of downtime. To properly troubleshoot bad welds, we must have […]

6 Levels of Welding Quality Standards

Which one do you fall under?

A question we often ask of our customer is “how to do you determine the minimum level of quality for your welded product and how do you verify you are reaching or exceeding that quality level?” Responses included comments such as: We just weld and know our welds will hold because we know our trade […]

Are Concave Fillet Welds Bad?

You may be surprised to know that sometimes they are desired

The following is an exerpt from: TROUBLESHOOTING FOR NON-WELDING ENGINEERS There is nothing wrong with concave welds so long as they attain the desired throat dimension. AWS D1.1/D1.1M:2020 Structural Welding Code (Steel) states that “there is no restriction on concavity as long as minimum weld size (considering both leg and throat) is achieved.” Concave welds […]

What is Stress Relieving and Why We Need It

Stress relieving is a form of post weld heat treatment. In stress relieving we heat a material to a specific temperature; hold it at this temperature for a specified amount of time in order to reduce or eliminate residual stresses; and then cool it at a slow enough rate to prevent these stresses from redeveloping. […]