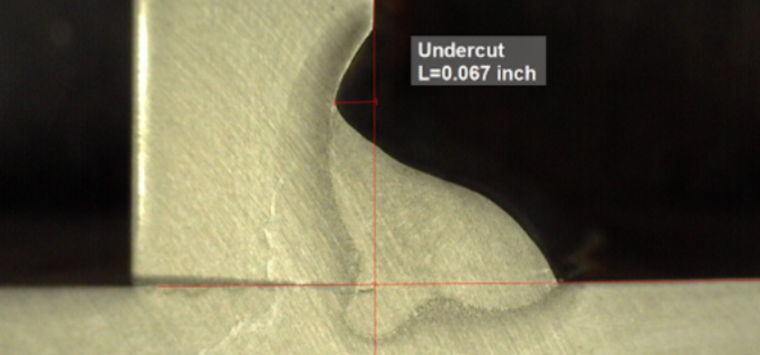

Undercut is a surface discontinuity resulting from melting of the base metal at one or both toes of a weld which remains unfilled by the weld metal. It can also occur at the root of groove welds. Undercut presents two problems. First, it forms a mechanical notch which acts as a stress riser and is particularly dangerous in cyclically loaded applications as it can facilitate the start of a crack. Second, if undercut is extreme it will reduce the net cross sectional area of the base metal to unacceptable levels.

AISI 4140 shaft fatigue failure. Crack intiation caused by undercut, propagation due to cyclic loading and brittle fracture of crack grew to critical size.

The above images show the fractured surface of a shaft. The material is AISI 4140 which means it is high in carbon and highly susceptible to cracking. Preheat was not applied prior to welding. The welding process used GMAW wire. Not using preheat was a huge mistake, yet this was the only shaft to have failed in service out of more than 300, at least to that point. So why hadn’t more failed? Well, this particular one had a welding discontinuity that was not detected by visual inspection: Undercut.

The undercut, being a mechanical notch, created perfect conditions for the start of a crack. This shaft was cyclically loaded and with each cycle the crack kept growing. The growth was extremely slow, approximately 0.002 inches per day. It took about 18 months before it failed. Once the crack grew to a critical size the part experienced brittle fracture. While crack propagation occurred at a rate of 0.0000000019 feet per second, the crack that caused brittle fracture occurred at a speed of 7,000 feet per second!

The problem with brittle fracture is that there is no warning. In ductile failure parts experienced deformation before they finally fail. In brittle fracture there is no warning. If there is no inspection for a fit-for-service evaluation, there will be no warning before catastrophic failure.

In the example above, undercut was only one cause of the failure. But if the undercut was detected during inspection and fixed, or if it had not occurred in the first place this failure probably would not have happened.

What causes undercut?

Factors that lead to undercut include improper welding procedures, improper welder technique, high arc voltage, arc blow and the use of improper welding consumables.

Since undercut can be dangerous, structural welding codes such as AWS D1.1/D1.1M Structural Welding Code (Steel) provide maximum allowable limits. Acceptability of undercut levels vary depending on the following:

- Its size – depth and length

- Loading direction

- Loading type (cyclic or static)

- Thickness of members being joined

In general, undercut exceeding 1/32-inch [0.8 mm] in depth can become problematic.

Repairing undercut is not complicated as it can be done simply by filling the void with another weld. It is recommended that undercut repair procedures be created to avoid additional problems. In larger sections, repairing undercut with a very low heat input procedure may lead to severe problems such as hydrogen induced cracking.

Please note: I reserve the right to delete comments that are offensive or off-topic.