Regardless what position you hold, if you work in the welding industry you have heard of welding procedures specifications (WPSs). To some, a welding procedure simply means the selection of a few variables such as amps and volts. To others, these are the documents that govern all welding done in their facility.

A welding procedure is a document that specifies how welding is to be done. It provides instructions to the welder that are used to set the welding parameters and properly prepare the welding joint. Welding procedures can be written in many different formats. Several of the welding codes and other specifications, such as API 1104, AWS D1.1, AWS B2.1, AASHTO/AWS D1.5, ASME Section IX and many others have their own suggested formats. However, these formats are not mandatory. As long as the necessary information is detailed the format doesn’t matter.

Also, the suggested formats for these codes and standards are typical of “simple” procedures. There are welding applications that require WPSs that are supplemented with additional instructions, notes or other forms developed to suit specific requirements.

Most welding procedures, regardless of format, must have 9 components or sections. If your welding procedures don’t include all of these you may want to revise them before the next audit.

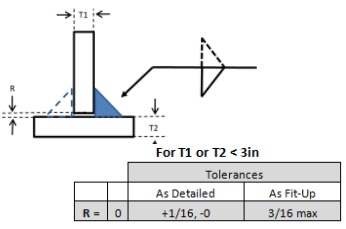

- Joint Design – provides information on the type of joint, dimensions and tolerances. It specifies if there is need for backing, backgouging or any other type of joint preparation. A WPS may also have a diagram of the joint as shown below.

- Base Metal – material number, subgroup (if any), thickness range that can be welded and the diameter if using tubular components.

- Filler Metal – specification of the filler metal, F- and A- numbers. It can also provide nominal chemistry composition if it is not a classified filler metal.

- Position – specifies the position of welding (flat, horizontal, vertical, overheat) including pipe rotation, if any. Also provides the progression (up or down) if welding in the vertical position.

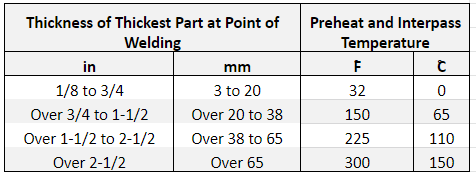

- Preheat and Interpass Temperature – provides the minimum preheat and interpass temperature. Some base materials will also require a maximum interpass temperature.

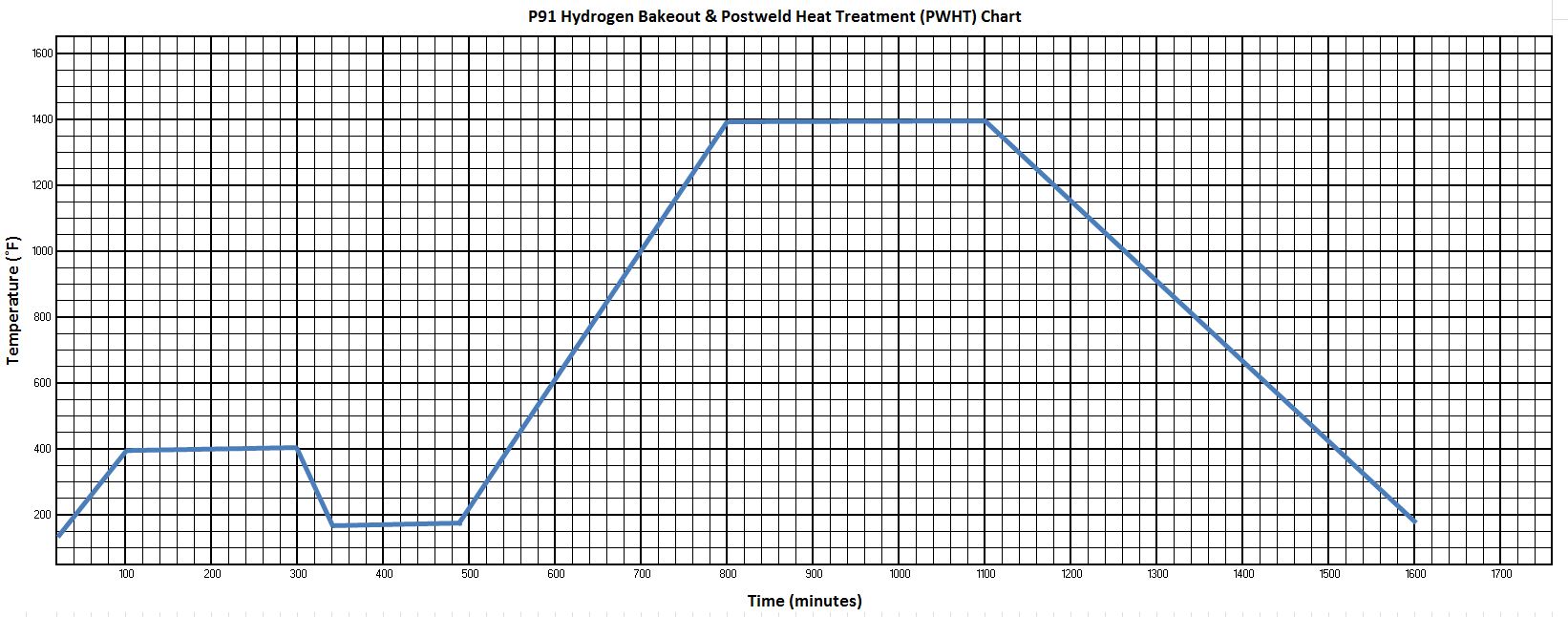

- Heat Treatment – this may include post weld heat treatment to prevent hydrogen induced cracking, to regain dimensional tolerance, to reduce or eliminate residual stresses and/or to achieve the desired mechanical properties. It will provide the heat treatment temperature and holding time.

Sample PWHT chart for P91 steel. Actual temperature and holding times are determined by material composition and thickness.

- Shielding Gas – shielding gas to be used, shielding gas components if it is a mixed gas including the percentage of each gas. Shielding gas flow rate must also be specified.

- Electrical Characteristics – this section specifies the current type (AC or DC) and polarity (+ or – for DC). It will also specify the mode of metal transfer.

- Welding Variables (Procedure) – in this section the wire feed speed (and/or amperage), voltage, travel speed, contact tip to work distance, work and travel angles are specified.

Not all WPS forms will follow this format, but they should all include the information above. WPSs, as noted above, may have additional notes or details.

Very informative, simple, easy to understand, and to the point. Thanks!

You’re welcome! Thanks for visiting our site.