Welding joints vary widely but can be traced back to a few basic joint types. Typically we hear terms like fillet weld, butt weld, lap weld or corner weld. These are all all joints but within these there are variations. Below we outline the joints and provide a graphical representation. These joint types are categorized by how the plates come together, and further subcategorized by joint preparation.

BUTT JOINTS

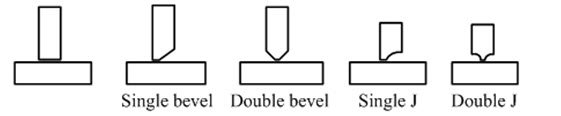

Butt joints consist of placing two plates side by side and joining to create a single piece. When plate thickness increases, or full penetration is desired, the plates are beveled. These are referred to as groove welds. Beveling increases the amount of filler metal needed but insures higher strength and proper penetration.

TEE JOINTS (FILLET WELDS)

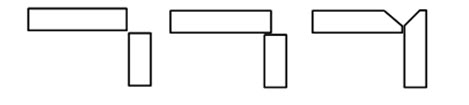

The tee joint has variations when a one of the pieces is beveled. As with butt welds, the bevel is used to achieved deeper or full penetration. It also requires less weld for equal strength on heavier sections.

CORNER WELDS

Corner welds are used to joint plates at 90 degree angles. Depending on material thickness it can be a straight butt weld, a lap weld, a fillet weld, or a groove weld.

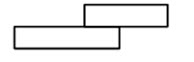

LAP WELDS

Lap welds are similar to fillet welds but the the size of the fillet typically reaches the top of one of the pieces.

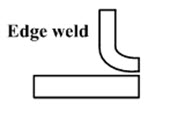

EDGE WELDS

Please tell me, in which welding type there are more chances of undercuts?

It is most common in MCAW and GMAW.

Which of the following types is not fill weld

which joint is considered as strongest joint?

good information on welding joints.

thanks

It depends on how the part is loaded and also on the size of theweld. In design, we want joints that are accessible, that minimize the amount of weld metal, and that allow for a strong enough weld to carry the loaded. You don’t always have a choice of joint but rather use whatever is allowed by the geometry of the structure. But, an example of when you would have a choices is joining two plates either on a butt joint or a lap joint. A complete joint penetration (CJP) weld will more than likely provide higher load carrying capacity that two lap joints which would be loaded in shear rather than pure tension. A bit hard to explain with words, but hopefully you get the picture.

Hello

Why outside-corner fillet weld isn’t proper for box column in steel structure?

Ì need your technical reasons for that question.

Thanks.

Hello Hanif, can you provide more detail on this question? Is this statically or cyclically loaded? If cyclically loaded, corner joints parallel to the direction of calculated stress between components of built-up members is prohibited by AWS D1.1 This could be due to the susceptibility of crack initiation due to surface or internal discontinuities. If you have access to a weld design engineer this should be brought to him or her and provide a lot more detail.