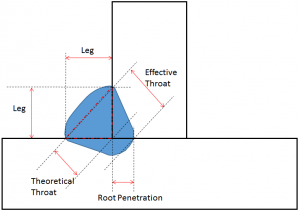

Measuring fillet weld legs is meaningless, well… not really. Fillet weld leg sizes are very important, but simply measuring the leg of a fillet weld does not tell us if we actually achieved the desired throat dimension. The strength of a fillet weld is determined by its effective throat. As you can see in the diagram below, the effective throat of the weld extends from the hypotenuse (the hypotenuse of the largest right-triangle that can fit on the cross section of the fillet weld) to the deepest point of root penetration.

The depth of root penetration will vary considerably due the many essential welding variables, including welder skill and technique. Because of this, the assumption made is that we will at least achieve fusion to the root. Fusion to the root gives us our theoretical throat.

If you have worked with AWS D1.1 Structural Welding Code (Steel) you are probably familiar with the requirement: “…fillet welds shall have fusion to the root, but not necessarily beyond.” Based on this structural code requirement, the welding procedures we develop for fillet welds must, at the very least, achieve root fusion every time. Why is this important?

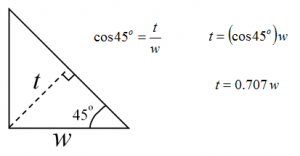

As stated above the strength of a fillet weld is determined by the effective area of the weld. The effective area of the weld is calculated by multiplying the length by the throat (theoretical throat). The length of the weld is easy to measure, but if we are not cutting up welds and doing macro etches how can we calculate the throat (t)? To do this we employ basic algebra.

To get the throat size for an equal-leg fillet weld simply multiple the leg size (w) by the cosine of 45˚, which is 0.707. So a 0.330 leg would yield a 0.330 x 0.707 = 0.233” throat.

This is why leg sizes are called out for fillet welds. If we know the leg size, and make the assumption we are following code requirements, we know that the throat of the weld is going to be at least 0.707 times the leg size (w).

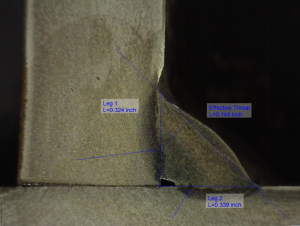

The reason for the title of this article (Fillet Weld Leg Sizes Are Meaningless) is because unless you can guarantee that root penetration was achieved you cannot be assured that the desired weld strength was met. Take a look at the weld below.

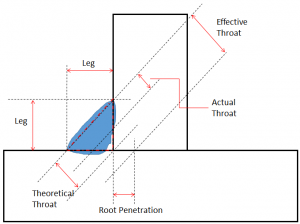

This cross-section macro etch of a fillet weld reveals that the welder was not even close to achieving root fusion. Not only that, if you pay close attention to the fusion line on the vertical plate you’ll notice that there is only fusion from the toe of the weld to just over halfway down to the root. This is represented in the image below (shown on opposite side of the joint).

You can now more easily see the drastic difference in the dimension of the actual throat which determines the strength of the weld and the theoretical throat.

Looking at the macro etch we see that the dimension of the actual throat was 0.144 inches. The leg size was about 0.330 inches so the theoretical throat is 0.707 x 0.330 = 0.233.

Because our throat is 38% smaller our effective weld area is 38% less. And since the strength of the weld is directly proportional its effective area, the maximum force this weld can sustain is 38% less than intended.

This is a perfect example of why welding procedures should be qualified. Regardless of what code or standard you are working with, qualifying your welding procedures is essential to ensure quality.

Please check your trig equation for determining leg lengths based on angles. If I’m not mistaken, the equation should actually use sin(45) instead of cos(45). These values are equivalent for this angle so the answer will be the same, but algebra/trig tells us the sin(theta) = Opposite / Hypotenuse. In the diagram above t is opposite the 45 degree angle and w is considered the hypotenuse.

You are correct Carl. With equal leg fillet welds the value of the adjacent side and the opposite side are exactly the same, so either cosine or sine will yield the right answer. However, if design called for unequal legs then using cosine would be wrong. Thanks for pointing this out.

Thank you

Well explained, thanks