Have you ever wondered, or have you ever been asked how many inches of wire are in one pound of filler metal? You may have been asked something like: “How many inches of wire are there in a 25LB spool of .035” ER70S-6 mig wire?” Typically, this questions is asked when someone is trying to estimate costs or find out how long this spool will last at a given wire feed speed.

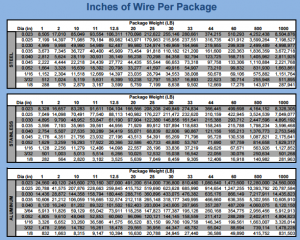

You can download your free Cheat Sheet for Inches of Wire per Package (of wire) here. You can also keep reading below to see how we can calculate this for any diameter, and not just the common ones such as .023”, .025”, .035”, etc.

Please note, these calculations are for solid wires only and do not apply to flux-cored or metal-cored wires. The calculation is simple, but we need to know the following:

- Filler metal type (carbon steel, stainless steel or aluminum)

- Specific density of the material

- Diameter of the wire

- Weight of package (weight of filler only)

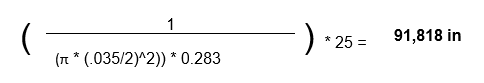

What we are calculating is the volume of material and then multiplying it by the density of that material to arrive to our answers. The density of steel and stainless steel are pretty close (0.283lb/cu-in and 0.289lb/cu-in respectively). The density of aluminum is 0.098lb/cu-in so please be careful to use the right density.

Our formula is the following:

where,

π = 3.14159where,

D = wire diameter

d = density of filler metal

Once we have inches per pound all we need to do is multiply this number by the number of pounds per package. So, per the example above the number of inches of .035” ER70S-6 per 25-pound spool is:

is there not an extra parenthesis after the ^2?

Yes, you are right. It is an image so unfortunately I cannot edit it at the moment, but I will get it fixed. Thanks for catching that.

As you mentioned, this analysis can be implemented in compact wires. How can you adjust the formulas in order to do the same calculations in the case of FCAW??

Hello Marios. Calculating this for flux-cored welding wire is more complicated since the sheath is never truly consistent. The thickness will vary from manufacturer to manufacturer. The density of the flux would also play a big role. Unfortunately we don’t have an easy answer for this one.

Very useful, thanks!