Category Archives: GMAW Process

Troubleshooting Welding Burn-through

Burn-through is a common defect in welding of light gauge materials. It is typically results in costly scrapping of parts since it can be difficult to fix. Or, if left in place when there are not structural integrity concerns it looks awful and portrays extremely poor quality. The following is an excerpt from our guide: […]

Which Welding Process Produces the Strongest Welds

SMAW, GTAW, GMAW, FCAW, MCAW or SAW?

The Importance of Weld Repair Procedures

A repair procedure is necessary any time there is a defect in welding that must be corrected. The repair procedure is not just a welding procedure specification, but rather a set of instructions and rules on how to repair different types of defects. There is no standard format for a repair procedure, or a standard […]

AWS D1.1 Prequalified Welding Procedures

Prequalified WPSs for GMAW, MCAW, SMAW, FCAW & FCAW-S

Prequalified welding procedures must adhere to the strict requiremnts of the welding codes which permit their use. AWS D1.1 Structural Welding Code (Steel) is one that allows their use. Prequalified WPSs are exempt from testing becasue there is reasonable assurance that as long as all the requirements are met the deposited weld will be sound […]

Effects of Voltage on Weld Quality

Voltage is one of the most important variables in a welding procedure. It is also one that is sometimes misunderstood. You may ask five welders what effect voltage has on a weld and you may get five different answers. This is because voltage can do a lot of things, some good and some bad. Understanding […]

Which is the best shielding gas for MIG welding?

Today we received two different requests for help pertaining to shielding gas selection. The first caller requested a chart that tells them what materials can be welded with the different shielding gases that they had. They wanted a chart that can be provided to the welders to make sure they used the right gas on […]

Short-arc vs Globular Transfer in GMAW

What is the difference between globular and short-circuit transfer? Short-circuit is a mode of metal transfer in GMAW in which metal is transferred from the electrode to the weld pool via a series of electrical shorts. When the electrode (wire) touches the base material a short occurs and the arc goes out. At this point […]

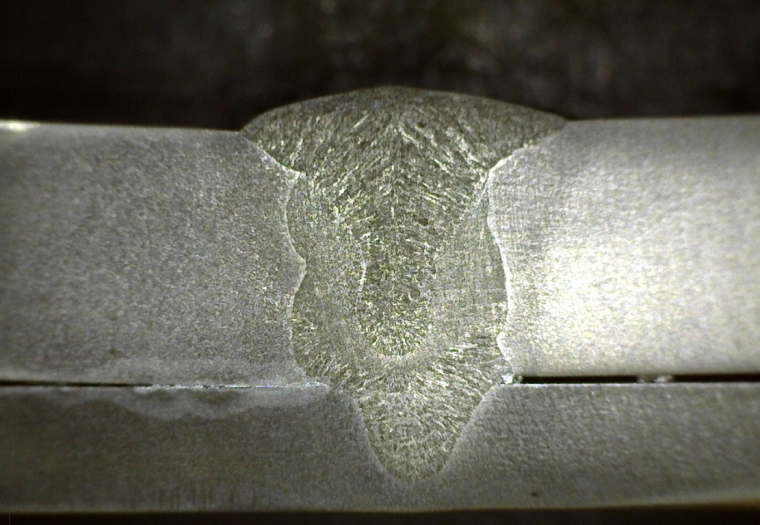

7 Variables That Affect Weld Penetration

Getting deeper penetration, or at least adequate penetration is very important in welding. There are a few applications in which we wish to minimize penetration, but in general we always want good penetration. There are many variables that affect penetration, some more than others. It is important to know how each individual variable affects the […]

Rainbow Colors in Stainless Steel Welding

Are they good or bad?

We receive several calls about welding stainless and the beautiful rainbow colors, or lack thereof, on the weld and heat affected zone. Is the tinting an indication of quality? Are these colors acceptable? Do they show that the weld had enough heat to penetrate? Why do they need to be cleaned? The questions are endless. […]