Have you ever been in a situation in which you need a qualified welding procedure immediately? Maybe you just failed an audit and have to halt production until a valid welding procedure is provided. Or maybe you’re just in a hurry to get started with a new job. Regardless of the reason you need the procedure quickly, there are a few ways to go about this.

For clarity, we are referring to needing a QUALIFIED welding procedure, meaning that it has been qualified by testing or prequalified according to the requirements of a welding code, specification or standard such as AWS D1.1, AWS D1.2, ASME Section IX, etc. We are not talking simply about a set of welding parameters to be used.

Your options to obtain a qualified welding procedure are the same regardless of the level of urgency. We’ll discuss these options and how quickly you can get your procedure. Here are your 5 options:

- Develop, test and qualify your own welding procedure

- Develop and document (or purchase) a prequalified welding procedure

- Purchase a Standard Welding Procedure Specification (SWPS) from the American Welding Society

- Get approval for the use of an existing welding procedure specification

- Obtain a welding procedure from a parent or sister company

Let’s look at these options in detail…

Develop, test and qualify your own welding procedure (1 to 4 weeks)

This is the most common way to arrive at a qualified welding procedure; however, it is not the fastest as the speed of testing the procedure to obtain a PQR is dependent on the third party performing the work. If you have special relationships with testing labs this may be done in a couple of days, or if you pay a very high fee for expediting. More realistically you are looking at 1 to 3 weeks for standard service depending on the lab’s workload.

Also, to go with this option you must be familiar and follow the requirements of the welding code you must conform to. If you don’t, you’ll need to hire a consultant that does and this can add to the cost, but more importantly to the lead time to get the procedure tested.

Develop and document [or purchase] a prequalified welding procedure specification (1 to 2 days)

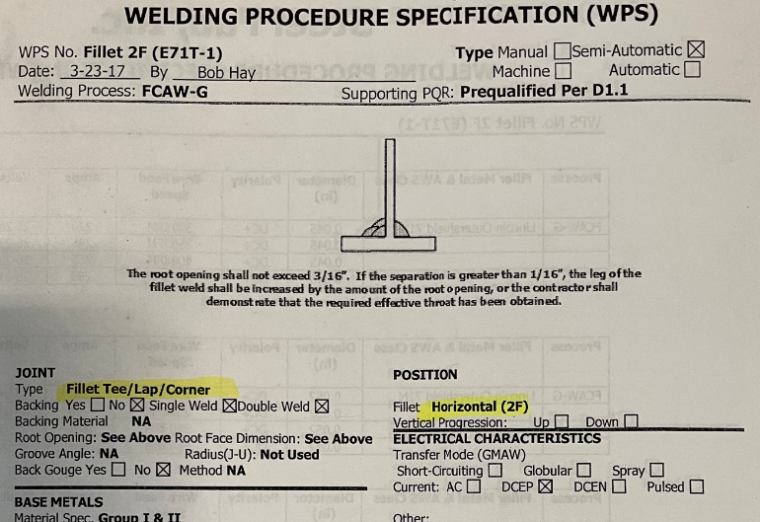

This is by far the fastest option provided the welding code, specification or standard you are following allows the use of prequalified welding procedures. Prequalified welding procedures are exempt from testing as long as you follow strict requirements and abide by certain limitations. Some of the most popular codes that permit the use of prequalified welding procedures are AWS D1.1 Structural Welding Code (Steel), AWS D1.3 Structural Welding Code (Sheet Steel) and AWS D1.6 Structural Welding Code (Stainless Steel).

These codes all have a clause for Prequalification. You can follow the instructions in these clauses and write your own prequalified welding procedure. A sound understanding of welding variables and their effect on quality and productivity is essential if you will write your own prequalified procedures. However, if you are lost when it comes to developing a procedure you can always hire someone or purchase prequalified welding procedures.

There are several providers that sell ready-to-use prequalified welding procedures. All you need to do is approve them for use and off you go. Keep in mind that the requirements imposed by the code on prequalified WPSs are there to ensure quality, but they may hurt productivity. This is why when selecting prequalified welding procedures you must opt for those that also maximize productivity.

If you have been a subscriber to our articles or visit our website often you know that is why we created a complete list of prequalified welding procedures for AWS D1.1 which covers the welding of Group I and II carbon steels ranging from 1⁄8-inch to unlimited thickness. You can get all 322 Prequalified Welding Proceedure Specifications or opt to go with only the welding process you are using. We created this library of procedures mainly to help steel fabricators that are trying to get quality under control and start working towards increasing productivity.

Purchase a Standard Welding Procedure Specification (SWPS) from the American Welding Society (1 day)

This may be the fastest option; however, the American Welding Society publishes Standard Welding Procedure Specifications (SWPSs) almost exclusively for applications that do not have the option of prequalification. This makes perfect sense of course! It is a great service by AWS. Some examples of what you can find in SWPSs are:

- Pipe welding welding procedures

- Welding on galvanized steel

- Welding dissimilar weld metals

- Applications requiring Post Weld Heat Treatment

- Combining filler metal or welding processes (i.e. E6010 root with 7018 fill and cap, or GMAW-s root followed by FCAW fill and cap on pipe applications)

All SWPSs fall under specification B2.1. For a complete list simply go to the AWS site, go to the Bookstore and in the search field type “B2.1” for a complete list of available SWPSs. The cost of these SWPS is approximately $250 for AWS members and $350 for non-members.

Get approval for the use of an existing welding procedure specification (1 to 5 days)

Don’t ever forget about the power of asking for permission. Whoever is the owner of the product you are building, and sometimes that is your own company, can approve the use of a welding procedure regardless of qualification status.

If you are building a product for a customer you can always reach out to them and ask if they can approve the use of an existing welding procedure without the need for testing. If your customer has a welding engineer or at least someone that understands welding variables they may be OK with using an existing procedure. The Engineer in charge can approve deviations from the contract documents which in many cases reference structural welding codes. So ask!!! This is not always a fast process, but it can be. Plan on a week if going this route.

Obtain a welding procedure from a parent or sister company (1 to 3 days)

Many codes allow the use of qualified welding procedures that were developed and tested for a specific company by a sister or other related company. If your company is owned by another company or owns other companies then see if they have a qualified welding procedure that applies to the work you are doing. It may be as simple as that.

Regardless of which option you choose to get your procedure be sure to do things properly in order avoid costly mistakes or further delays. Good luck!