Austenitic stainless steels are a cornerstone of many industries because of their exceptional corrosion resistance, strength, and aesthetic appeal. The most commonly used austenitic stainless steels are grades 304, 304L, 316, and 316L. This article, the first in a series, will provide an essential overview of these materials, highlighting their unique characteristics and why proper welding procedures and techniques are essential.

Before we get into today’s topic we would like to make you aware that in early March we will be releasing our new collection of Prequalified Welding Procedure Specifications for Stainless Steel. These will cover the most common grades in general fabrication: 304/304L and 316/316L. These procedures will be offered in similar format as our prequalified welding procedures for carbon steel which were released a couple of years ago. We’ll provide more information in the coming weeks. As with all of our initial releases we will have special offers for our valued readers and customers. Now, back to welding stainless steel…

What Makes Austenitic Stainless Steels Unique?

The term “austenitic” refers to the steel’s microstructure. These steels possess a face-centered cubic (FCC) crystal structure, which is stable at room temperature due to the addition of alloying elements like chromium and nickel. This structure contributes to their ductility, toughness, and, most importantly, their excellent resistance to corrosion. Let’s now look at what these alloying elements do:

- Chromium (Cr): The primary element responsible for corrosion resistance. Chromium reacts with oxygen to form a passive protective chromium-oxide layer on the steel’s surface.

- Nickel (Ni): Enhances toughness, ductility, and corrosion resistance.

- Other elements: Other alloying elements like molybdenum (Mo) and titanium (Ti) are added to modify specific properties, like increased corrosion resistance in 316 or stabilization in 321.

The Popular Grades: 304, 304L, 316, and 316L

These four grades are widely used due to their balanced properties and cost-effectiveness. Let’s break down the key differences:

- 304: The most common austenitic stainless steel. It offers good corrosion resistance in many environments and excellent mechanical properties. Commonly used in kitchen equipment, architectural applications, and general fabrication.

- 304L: The “L” stands for “low carbon.” 304L has a lower carbon content than 304, which makes it less susceptible to carbide precipitation during welding. This is crucial for maintaining corrosion resistance in the heat-affected zone (HAZ). This grade is ideal for applications requiring welding or where sensitization is a concern.

- 316: Offers superior corrosion resistance compared to 304, particularly in chloride-containing environments (like saltwater). This improved resistance is due to the addition of molybdenum. Used extensively in chemical processing, marine applications, and medical devices.

- 316L: Similar to 304L, 316L is the low-carbon version of 316. Its low carbon content minimizes carbide precipitation and enhances weldability and corrosion resistance after welding. The low carbon version is the preferred material for welding applications.

As you can see, lower carbon, as in the 304L and 316L grades are better suited for welding. Carbide precipitation is detrimental to corrosion resistance. This is a process by which carbon bonds with chromium. This forms chromium carbides and it reduces the amount of chromium available to bond to oxygen to form the desired corrosion resistance layer (chromium oxide).

Why are welding procedures critical for welding austenitic stainless steels?

While austenitic stainless steels are known for their robustness, improper welding practices can severely compromise their properties. Here’s why:

- Corrosion Resistance: Welding introduces heat, which can alter the steel’s microstructure and lead to carbide precipitation (especially in higher-carbon grades). This reduces the corrosion resistance of the HAZ as explained above. Choosing the correct filler metal and using a welding procedure that controls heat input and interpass temperature is critical.

- Mechanical Properties: Overheating or improper cooling can affect the steel’s strength, toughness, and ductility. This could lead to premature failure of the welded joint. With austenitic stainless steels we typically desire a rapid cooling rate (unlike most carbon steels) because it reduces susceptibility to sensitization (see below).

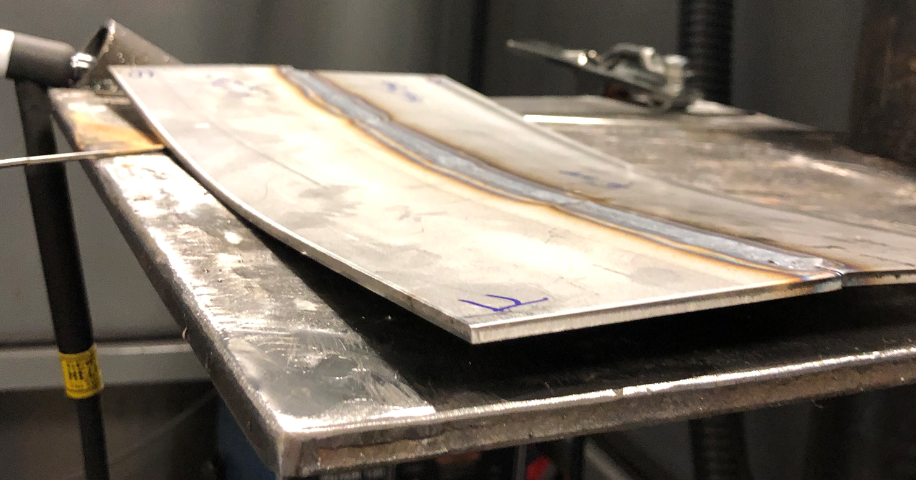

- Distortion: Stainless steels have a higher coefficient of thermal expansion than carbon steels, making them more prone to distortion during and after welding. Controlling weld size, heat input and using adequate distortion control techniques is a necessity.

- Sensitization: When stainless steel is heated to a specific temperature range (800-1500°F or 427-816°C), chromium carbides can form at the grain boundaries. This “sensitization” depletes the chromium available for corrosion resistance, making the steel susceptible to intergranular corrosion. Low-carbon grades (304L and 316L) and stabilized grades (321) are designed to prevent this.

Applications of Austenitic Stainless Steels

As already mentioned, austenitic stainless steels are widely used . Their versatility allows for a wide variety of applications such as:

- Food and Beverage: Processing equipment, storage tanks, and kitchenware.

- Chemical Processing: Reactors, pipelines, and storage vessels.

- Medical: Surgical instruments, implants, and hospital equipment.

- Architectural: Building facades, railings, and decorative elements.

- Marine: Boat fittings, offshore structures, and desalination plants.

- Oil and Gas: Pipelines, refineries, and platforms.

Over the next 3 weeks we’ll be sharing additional information on welding austenitic stainless steels. We will dig deeper into metallurgy, welding processes, filler metal selection, and more.

Glad your helping us learn more about welding.

It is our pleasure!

Excellent article….

Thank you! We are glad you find it useful. We will be diving deeper into the metallurgy of stainless steels and the importance of it for weldability in our next article.