Have you ever had your eyes burned by the welding arc rays? Was it because you didn’t wear safety glasses at work? Or did you weld without a welding helmet? Regardless of the reason, if you got an arc burn you better be ready for a very unpleasant night. If you burn your eyes at work you will probably wake up in the middle of the night feeling like you have sandpaper in your eyes. If you open your eyes it will hurt. If you close your eyes it will hurt even more. Think eye drops will help? Get ready for more pain. Unfortunately there is very little you can do to help with this other than suck it up and wait it out.

If this does happen to you, go to your freezer and get some frozen peas or some other frozen vegetable and place it over your eyes. This will provide a bit of relief. After 2 to 3 hours of this you may fall back asleep from pure exhaustion and, if you’re lucky, you’ll feel better by the time you need to go back to work the next morning.

Now why would you let this happen?

It still amazes us the number of fabricating shops we visit in which eye protection is not mandatory. However, what’s even crazier is that we as individual still choose to tack, weld, grind and cut without eye protection. Regardless of your employer’s stance on safety, you must always take care of yourself. More than likely there are several people at home that depend on you, so do the responsible thing and be safe.

We all know safety glasses are not worn for fun or to make a fashion statement. We wear them to protect our eyes from flying debris, grinding dust, welding spatter and sparks, and ultraviolet radiation from the welding arc.

The human eye is very susceptible to corneal abrasion. Small objects such as grinding dust can easily enter your eye and damage the surface of the cornea. Simple measures such as wearing safety glasses can save you from injury.

However, wearing safety glasses can be uncomfortable. They get scratched up and it makes it hard to see. They get foggy making it necessary to take them off constantly to wipe them down. Maybe they bump against your welding hood. All of these things are annoying but not as much as missing work to go to the emergency room. If your safety glasses have any of these issues, spend the $3 to buy another pair. Most employers provide these for their employees and may only cost you a 2-minute walk to the supply room.

It is important to note that when welding you must still wear your safety glasses under the hood. The welding lens shade, if adequate for the type of welding being done, should provide all the protection needed from the harmful UV rays generated by the welding arc. But, if debris goes inside your helmet, not having safety glasses can cost you. Welding spatter from your arc or your fellow co-workers arc can always get inside your helmet. Protect your eyes by always welding with safety glasses.

Do you like to tack weld with your hood up? Or without a hood altogether? If all you are doing is tacking it is still necessary to wear a welding helmet. If you think you are saving time by doing this think again. If you weld without a welding hood you are risking damage to the cornea by the UV rays. If you go a step further and weld, even tack weld, without glasses it’s just a matter of time before you lose an eye.

One final note, if you are in a welding shop you must always wear safety glasses whether you are welding or not. The reflection of the arc against surfaces such as walls, screens, stacked steel, welding equipment and other surfaces can make the rays reach your eyes. You may not see it, you may not feel it, but if the rays are hitting the side of your eye you can certainly get arc burn.

Hopefully by now you are convinced that you should always wear safety glasses under your welding hood. But what about the shade number of your welding lens. Does it matter?

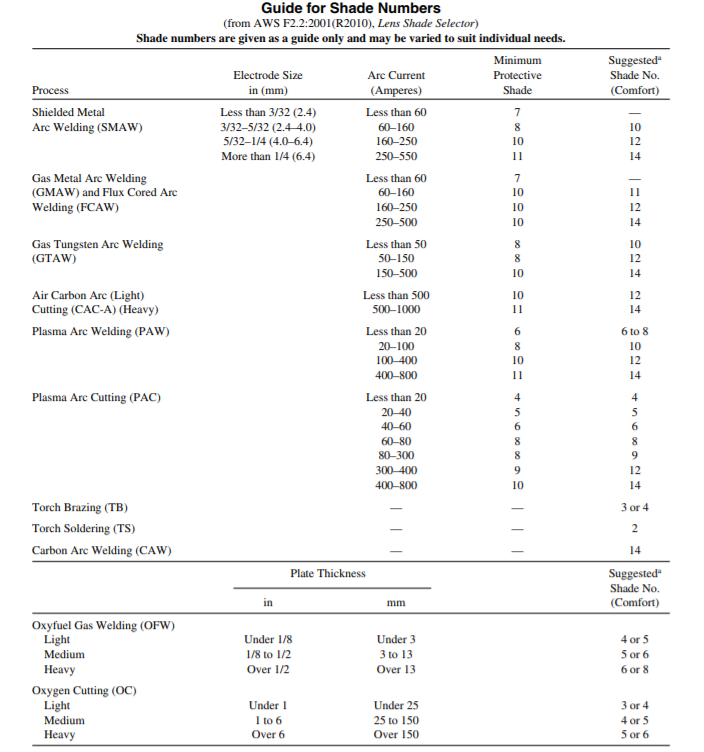

There are different shades used for welding. Shades 9-13 are the most popular and the usual choices for in most welding helmets. Automatic welding lenses now have the ability to switch the shade with a simple knob or push button. So whether you are welding GMAW in spray mode or cutting with oxy-fuel, you should have the option to select the appropriate shade.

The chart below is published in ANSI Z49.1 – Safety in Welding, Cutting and Allied Processes. This is a free publication which may be downloaded from the AWS website.

Note that there is a minimum shade number and suggested shade number depending on the process and/or amperage you are using. What we typically recommend when asked what shade number to use, is to go to the highest shade available and go down only if you cannot see the arc and the puddle clearly. Remember, your eyes are what’s at stake. Protect them.