Tag Archives: HAZ

Troubleshooting Weld Cracking – The importance of crack location

One of the first steps in analyzing cracks to find their root cause and take corrective action is to categorize the cracks. We categorize cracks based on three elements. Location Direction Timing In today’s article we discuss the importance of crack location when trying to determine what caused it. What follows is an excerpt from […]

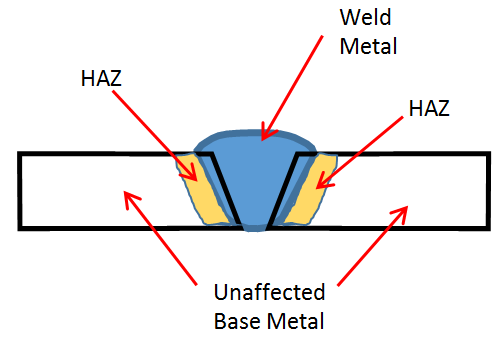

The Importance of the Heat Affected Zone (HAZ)

When we weld we generate enough heat in the welding arc to melt the filler metal and base material. Or just the base material is we are welding autogenously (as in GTAW without filler). The edges of the base material melt and combine with the filler metal to create what is called the composite zone. […]

5 MORE Questions You Should Know for the CWI Exam

And fundamental principles for the fabrication of steel structures

Today we’ll cover 5 more very important concepts that are governed by the AWS D1.1 Structural Welding Code (Steel). If you missed our last post with the first five questions simply click here. These concepts can show up as questions in the Certified Welding Inspector (CWI) Exam. As stated in our article from last week, […]

Factors Affecting Cooling Rates of Welds and Heat Affected Zones

Different ways to manage the rate of cooling

Our next article will discuss a question we are asked quite often: Can we eliminate preheating before welding? Preheating is necessary to slow the cooling rate down after welding which in turn avoids excessive hardening of the weld and heat affected zone. Eliminating preheat can lead to hydrogen induced cracking and catastrophic failure. A […]

Understanding Why Your Welds Crack – Part 3

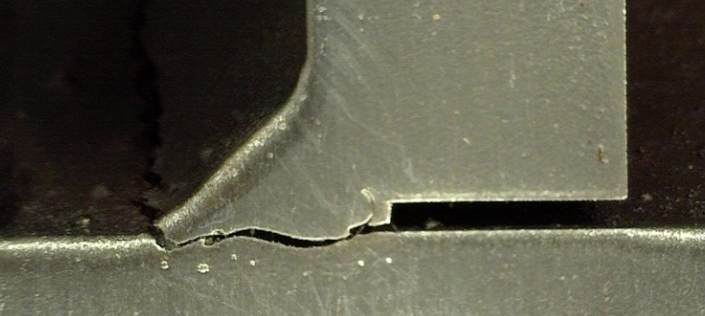

Location of Cracks

In our previous two articles we talked about categorizing cracks based on when they occur and in which direction they propagate. Today on our third and final article on understanding why your welds crack we look at the importance of location. If you want to review or if you missed our previous two articles simply […]

Why is Preheating Necessary?

Preheating steel before welding is common practice. Sometimes we apply heat after we are done welding as well. Other times we apply heat between passes to maintain the minimum interpass temperature. Many use preheat simply because it is written in the WPS, but not really understand why it is necessary. Preheating is used for […]