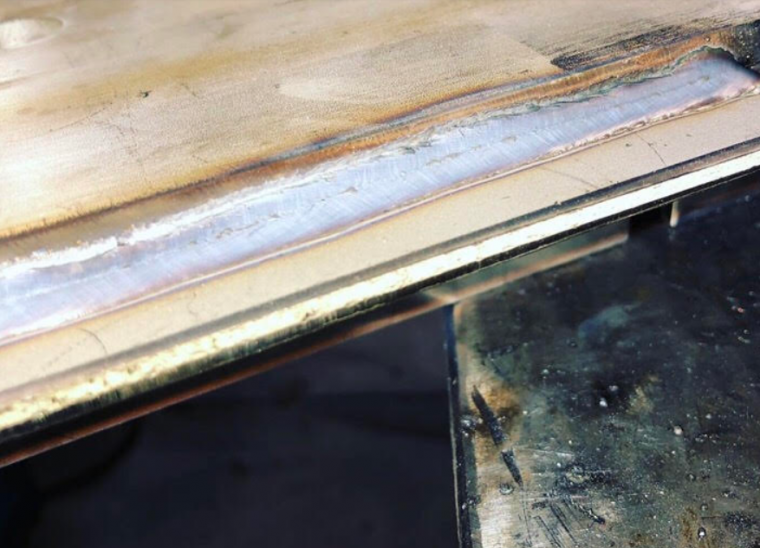

Factors Affecting Cooling Rates of Welds and Heat Affected Zones

Different ways to manage the rate of cooling

Our next article will discuss a question we are asked quite often: Can we eliminate preheating before welding? Preheating is necessary to slow the cooling rate down after welding which in turn avoids excessive hardening of the weld and heat affected zone. Eliminating preheat can lead to hydrogen induced cracking and catastrophic failure. A […]