Even for those of us dealing with welding all day every day it is difficult to remember the welding position nomenclature. So here is a quick cheat sheet.

Fillet Weld Positions

Groove Weld Positions

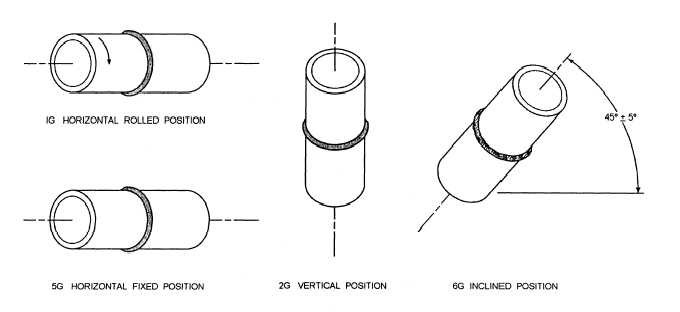

Pipe Weld Positions

Which do you consider to be the most challenging welding position?

hi there i only have a 2F weld code does this cover me for a 3G down hand open but 5mm plate with 5 mm grove thanks fr looking at this

Most welding codes will NOT allow you to use a 2F procedure for welding 3G, regardless of whether it is vertical up or vertical down.

I am interested in welding position and qualfieng welders.

8

Are you qualifying welders to a specific code? Or do you just need to qualify welders or internal purposes or to satisfy a customer requirement? What kind of help do you need? A couple of resources that might help are:

Free qualification checklists to follow using D1.1 https://welding-answers.lpages.co/qualification-checklists

Complete guide to the qualification of welders and welding procedures using AWS D1.1 https://welding-answers.lpages.co/procedure-and-welder-qualification-guide

If you have specific questions let us know.

Welding guide will be very useful for me.

From a standpoint of welder performance qualification tests then the 2F position is the most difficult to get to pass. The ability to obtain fusion at the root on 2 thick plates is not as easy as one would think. The travel speed, arc length, deposition rate, and especially travel angle can influence the amount of penetration. There have been many a welders fail this one.

These can also be difficult to inspect. A good polish and etch is needed. The fracture surface after the bends are done has to be looked at closely to verify complete penetration.

Anything overhead. Always forget to wear a beanie!