It is very common to weld stainless steel to mild steel. But, when it comes to qualifying a welding procedure it can be somewhat confusing. Do you follow AWS D1.1 (Steel) or do you following AWS D1.6 (Stainless Steel)? Or is there another code or standard you should use?

The answer to this question is all of the above. You can use both AWS D1.1 and AWS D1.6. Which one to use depends on your customer’s requirements. This will typically be spelled out in the contract documents. In both cases you will probably be welding an approved base metal to a non-listed base metal and qualification of the welding procedure must be done by testing.

Alternatively you could use AWS B2.1 – Specification for Welding Procedure and Performance Qualification. This standard is very useful when you are trying to qualify procedures for many different metal types and a single structural welding code, such as AWS D1.1, does not cover all. This specification does not allow for the use of prequalified welding procedures. However, standard welding procedure specification (SWPSs) can be used. More than likely you’ll be doing all your qualifications by testing.

Mild steel and stainless steel are commonly welded using 309LSi filler metal. Qualification of welding procedures should be done by testing.

In order to qualify a procedure for welding a mild steel base metal such as ASTM A572 Grade 50 to alloy 304L (stainless) you can follow AWS D1.6 Structural Welding Code – Stainless Steel and follow the steps below.

The first step should be to determine if a prequalified welding procedure specification (PWPS) can be used. Clause 5 (Prequalification) of AWS D1.6 Structural Welding Code (Stainless Steel) lists all approved base metals for use in PWPSs in Table 5.2. Unfortunately in this case, ASTM A572 Grade 50 is not approved for prequalification of a WPS.

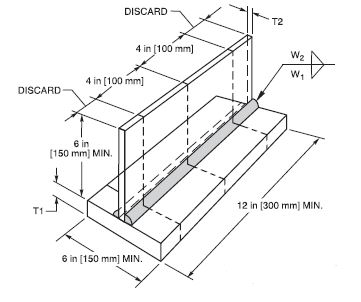

Since we cannot used a PWPS it is necessary to qualify the WPS by testing. For this, we need to jump to Clause 6 in AWS D1.6 – Qualification. This Clause specifies the necessary tests, test plate or pipe configurations and sizes, necessary destructive tests, visual inspection requirements and acceptance criteria.

Table 6.1 – Essential Variables for Procedure Qualification, outlines the variables that if changed over a specified amount would require requalification.

Table 6.3 – PQR Type, Number of Test Specimens, and Range of Thickness Qualified for Procedure Qualification, is one of the most important tables in this case. It provides the thickness range qualified based on the thickness of the test specimen. It provides ranges of deposited weld metal thickness qualified. And just as important it spells out the necessary type and number of tests required. Depending on the weld type and material thickness one or a combination of the following tests will be required:

- Marcroetch

- Reduced section tension test

- Side bend

- Face bend

- Root bend

Destructive testing acceptance criteria can be found in Clause 6.9.3 Types, Purposes, and Acceptance Criteria for Qualification Testing.

Before these destructive tests are carried out Visual Inspection (VT) must be completed. Table 8.1 – Visual Inspection Acceptance Criteria, outlines all acceptable limits for surface welding discontinuities such as:

- Cracks

- Fusion requirements

- Craters

- Weld profiles

- Undersized welds

- Undercut

- Porosity

Allowances vary depending on whether the application involves static loading or cyclic loading.

If all the tests meet the acceptance criteria for both destructive and nondestructive testing then the WPS is approved a procedure qualification record (PQR) is created. The PQR support the WPS. The PQR lists the specific values for all the variables used in the test. The WPS can specify ranges to be used in production based on the allowances of the code and based on the values stated in the PQR.

If you have worked with AWS D1.1 Structural Welding Code (Steel) you’ll notice that there is basically no difference in the qualification tests as what was discussed above. There was no mention of corrosion resistance. Any requirements for corrosion should be specified in the contract documents and accelerated corrosion tests must be carried out. This is beyond the scope of AWS D1.6 and other standards must be used.

The qualification of welder performance will follow similar rules as D1.1. Qualification tests will be subjected to both visual inspection and destructive testing. Upon passing a welder performance qualification record (WPQR) will be created.