A weld failure is never good. Whether a weld cracks on a truck’s axle or on the post holding your house’s fence, there are always consequences. Hopefully the consequences are limited to time and money. Unfortunately, weld failures can cause injury. Welds can fail due to design flaws, but the majority of weld failures occur due to reasons we as welders can prevent.

Probably the single, most important tool for preventing cracks is the Welding Procedure Specification (WPS). The use of WPS is not simply to comply with an internal or customer requirement, it is to insure quality. With this being said, we should not follow a WPS blindly, if there is something we believe is not right we must bring it up to our supervisor’s attention.

Lets look at the most common types of cracks, their possible causes, and how to prevent them.

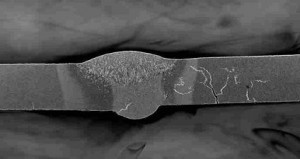

1. Heat Affected Zone Crack

The heat affect zone (HAZ) of a weld is not limited to the weld itself but to the immediate area of parent material surrounding the weld. A HAZ crack can originate at the toes of the weld or a few millimeters from the weld altogether. The most common causes for this type of crack are: excess hydrogen, high residual stress levels on the weld, and high carbon content on the base material.

To minimize the susceptibility or prevent HAZ cracks consider:

- using low hydrogen electrodes

- pre-heating the base material

- slow cooling the base material after welding

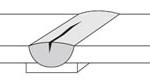

2. Centerline Crack

Also know as longitudinal crack, a centerline crack will typically extend the length of the weld. This type of crack is most often caused by an improper width-to-depth ratio, low melting point of tramp elements in the base material, and a concave weld surface. Although a single one of these can be the root of the problem, most often it is a combination of these that cause a weld to crack.

To reduce the chance of a centerline crack consider:

- aiming for a width-to depth ration of 1:1 to 1.3:1

- run lower current to decrease excess penetration

- decrease welding voltage or slow travel speed to achieve a flat to convex weld surface

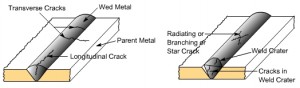

3. Crater cracks

Most common in aluminum welds, the crater crack is due to lack of fill at the the end of the weld. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials.

To eliminate crater cracks insure proper crater fill by:

- backstepping at the end of the weld (reach the end and then weld back over the bead for 1/2 to 1 inch

- use welding equipment crater fill option (if available)

4. Transverse cracks

Transverse cracks are not very common outside of harfacing welds. However, they due occur and are caused by: high residual stress, excessive weld strength, and excess hydrogen.

To minimize susceptibility of transverse cracks cosider:

- pre-heating the base material

- using lower strength consumables

- slow cooling after welding

As mentioned above, the most important tool to prevent cracks is a welding procedure specification that has been qualified by testing. Some fabricators must follow specific codes such as AWS D1.1, AWS D1.2, API 1104 or ASME Section IX for the qualification of welding procedurs and welders. Codes are used to ensure quality and prevent failures. Although the most commonly used welding codes vary in certain regards, they all require that both welding procedures and welders be qualified by testing. Some codes sometimes allow the use of Prequalified Welding Procedures which can save time and money. If you are not sure if a prequalified WPS can be used always err on the side of caution and qualify by testing.

Do you want more information on how you can peform your own procedure and welder qualifications?

Do you want more information on how you can peform your own procedure and welder qualifications?

“Qualifying Welding Procedures, Welders and Welding Operators” is a guide developed to help you peform your own qualifications in full compliance to AWS D1.1 Structural Welding Code – Steel.

Looking for the best definition of HAZ and why it should be included as part of the finished weld final inspection.

Wanting to defend including the HAZ in the final NDE if the weld. ASME NB identifies 1/2 inch on either side.

Many thanks.

Hello Wayne. The HAZ is the base metal adjacent to the weld that got heated enough to undergo a microstructural change but not enough to melt. The microstructural change depends on the cooling rate (product of the welding heat input, any preheat temperature, volume of the part being welded) and on the chemistry of the base metal. The changes that can occur are many. They range from softening to hardenning. From reduced ductility to higher ductility, etc.

What type of inspection of the HAZ are you proposing?

Looking forward to the info sharing.

We have welded some 4″ sch 10 SS304 pipe and we find that it is cracking about 8 to 10mm away from the weld join in the parent material. The cracks do not start or end in the weld metal they run parallel to it and they re outside the HAZ. (photos available.) They appeared about 4 or 5 days after the job was commissioned. The pipe transports borehole water from the borehole to a tank at about 6 bar max. The welders are all good welders and these same welders have done lots of other jobs at our factory with very good results and continue to get good results on subsequent jobs. We have concluded that the pipes are an inferior material and are “Fake 304” !

Does anyone have a similar experience that can shed some light?

Hello Adam, please send the pictures to us by email so we can evaluate.

Central crack mig co2 spots welding

Steel wire copper coating

Your first line of your article mentions a truck axle. We have been seeing a lot of axle failures and the axle company in central MO says they use a robot weld and it is not there fault. All failures have been the weld. All of the re-welded welds hold but they clam no responsibility and they note that they know what they doing. By the looks of all failures they are clueless about welding. There are cracks on the top and the root of the weld is incomplete. The fusion to the axle is little to none. Again they state that it meets there expectations. What do we do?

A manufacturer that claims no responsibility for weld failures without proper investigation certainly sounds a bit fishy. Assuming that the axles are being used per the manufacturers specifications (not exceeding limits or being misused), they should not fail. We can learn a lot simply by looking at the failed part. If it is evident that there is lack of penetration at the root then it is NOT a good weld. The strength of the weld is determined by the effective throat, which extends form the face of the weld all the way to the point of deepest penetration. If a weld size is called out it assume there will be root penetration. In this case the strength of the weld is reduced drastically.Putting the axle under “normal” working conditions could certainly create a weld failure in this case.

Welding with a robot does not guarantee quality. Torches crash, operators touch up points, wire may not be coming out straight, etc. All these things can cause bad wire placement and prevent good root penetration.

The first step to get some resolution (if your supplier is not helping) would be to contact the manufacturer of the equipment and/or welding wire being used. Depending on the company they can sometimes provide a lot of assistance in failure analysis at little or no cost.