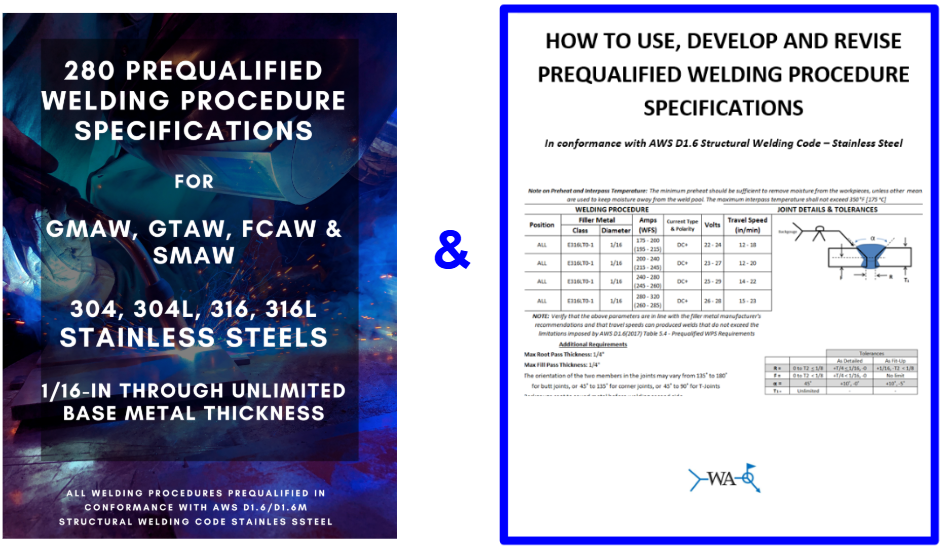

We are excited to officially release our latest collection: 280 Prequalified Welding Procedure Specifications for Stainless Steel

As we mentioned during our preview last week, these welding procedures have been developed and prequalified in conformance with AWS D1.6/D1.6M Structural Welding Code – Stainless Steel.

These welding procedures were put together for:

- Business owners and managers that want to bring consistency to welding operations in regards to quality and productivity

- Fabricators looking to have AWS D1.6 Code approved welding procedures to comply with contract requirements

- Welding supervisors and CWIs needing qualified procedures for purposes of testing welder performance

- CWIs looking to have a comprehensive library of welding procedures for use at their place of work or when working with their customers

- Quality control personnel looking to create welding quality control standards

- Schools looking for prequalified WPSs to be used for welding program curriculums

The 280 prequalified welding procedures contained in this package cover GMAW (mig), FCAW-G (gas-shielded flux-core), GTAW (Tig), and SMAW (stick). They cover 14 of the most commonly used weld joint configurations, all prequalified by AWS D1.6. The base metals covered are 304, 304L, 316 and 316L. Instructions are provided to modify these procedures to use other alloys and other filler metals and retain prequalified status.

Prequalified welding procedures included:

- 42 WPSs for GMAW – 304/304L to 304/304L and/or 316/316L (Mig .035″, .045″, 1/16″ diameter ER308L/ER308LSi wires)

- 42 WPSs for GMAW – 316/316L to 316/316L (Mig .035″, .045″, 1/16″ diameter ER316/E316L wires)

- 28 WPSs for FCAW-G – 304/304L to 304/304L (Flux-core Gas-shielded .045″, 1/16″ diameter E308L wires)

- 28 WPSs for FCAW-G (Flux-core Gas-shielded) – 316/316L to 316/316L .045″, 1/16″ diameter E316L wires)

- 14 WPSs for GTAW – 304/304L to 304/304L and/or 316/316L(Tig 1/16″, 3/32″, 1/8″, 5/32″ diameter ER308L/ER308LSi filler rod and 1/16″, 3/32″, 1/8″, 5/32″ diameter EWTh-2 tungsten electrode)

- 14 WPSs for GTAW – 304/304L to 304/304L and/or 316/316L(Tig 1/16″, 3/32″, 1/8″, 5/32″ diameter ER316L/ER316LSi filler rod and 1/16″, 3/32″, 1/8″, 5/32″ diameter EWTh-2 tungsten electrode)

- 56 WPS for SMAW – 304/304L to 304/304L and/or 316/316L (Stick 3/32″, 1/8″, 5/32″, 3/16″ E308L-15, E308L-16, E308L-17 diameter electrodes)

- 56 WPS for SMAW – 316/316L to 316/316L(Stick 3/32″, 1/8″, 5/32″, 3/16″ diameter E316L-15, E316L-16, E316L-17 electrodes)

SPECIAL BONUS: When you make your purchase you will receive for free a guide that was written to guide the user on How to Use, Develop and Revise Prequalified Welding Procedure Specifications and maintain AWS D1.6 conformance.

For more information or to get your welding procedures >>> go here.