Preheating of structural steels is carried out primarily to slow the cooling rate after welding and prevent the formation of martensite. Martensite makes the weld and the heat affected zone (HAZ) very hard and brittle. This newly formed microstructure is susceptible to cracking. By slowing the cooling rate we reduce or eliminate the formation of martensite and thus reduce cracking susceptibility. For more information on why we preheat read Why Is Preheating Necessary.

Two of the most common questions we receive from our customers in regards to preheating are:

- Do I need to preheat this material (the steel they will be welding)?

And,

- To what temperature must I preheat?

There are different ways to determine what the preheat temperature should be. The benefit of some of these methods is that you can determine the preheat temperature not based on a safe standard, but rather based on the material’s chemistry. By doing this you can determine that the preheat temperature is much lower than that published in tables such as Table 3.3 of AWS D1.1 which states the minimum preheat and interpass temperatures for all structural steels. This can end up saving you a lot of money by reducing the preheating time and reducing fuel consumption. To learn about the different ways to determine preheat read 5 Methods To Determine Preheat Temperature.

Preheating is used primarily to reduce the cooling rate of the weld, heat affected zone and adjacent base metal. This reduces susceptibility to cold (hydrogen induced) cracking.

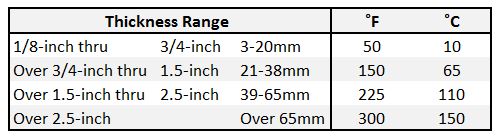

But if you are just doing a small job and only need a safe preheat temperature we refer to Table 3.3 mentioned above. In many cases we are not given the exact information on the type of structural steel or even the welding process that will be used. Because of this we provide the preheat temperatures listed below.

Please note that these preheat temperatures may be much higher than that required for a specific steel. But this table is just here to provide a temperature that will work for you. If you will be doing a lot of preheating we suggest you figure out the exact temperature by one of the 5 methods to determine preheat temperature.

The necessary preheat temperature depends on 3 things:

- Whether or not a low-hydrogen process is used

- The thickness of the steel

- The chemistry of the steel

Some steels should not be welded with anything other than low-hydrogen electrodes. Be sure to use the right electrode for the steel you are welding. Assuming you are using the right electrode the table below provides safe preheat and interpass temperature for structural steels. Structural steels as defined by AWS D1.1 Structural Welding Code as carbon or low alloy steels that are 1/8 in [3 mm] or thicker with a minimum specified yield strength of 100 ksi [690 MPa] or less.

A few additional points to keep in mind:

- When the base metal temperature is below 32°F [0°C], the base metal shall be preheated to a minimum of 70°F [20°C] and the minimum interpass temperature shall be maintained during welding.

- For ASTM A709 Grade HPS 70W and ASTM A852, the maximum preheat and interpass temperatures shall not exceed 400°F [200°C] for thicknesses up to 1-1/2 in [40 mm], inclusive, and 450°F [230°C] for greater thicknesses.

- The use of high heat input welding processes such as submerged arc welding (SAW) may allow for lower preheat temperatures

- Preheat temperature readings must be taken at a distance equal to the thickness of the thicker member being welded, but no less than 3 inches away from the joint just prior to initiating the arc for each pass.

- The preheat temperature should be at the specified value not just at the point where the weld starts but through the entire length of the joint.

- Minimum interpass temperatures should be the same as the preheat temperature unless otherwise specified in the welding procedure specification (WPS).

References:

Please update the preheat requirements for unlisted materials in AWS D1.1

Unlisted materials do not have a set preheat and interpass temperature. These should be determined by the Engineer in charge and shall be done by testing – meaning a PQR must be created after successfully passing the code required tests.

Hi, what if the material is unlisted (EN material)?.Will the reduced tension and bend tests required by D1.1 qualify the joints or shall I prepare a macro specimen and perform HAZ hardness?

Unlisted materials can still follow all the requirements of D1.1, so as you said the reduced section tension test is necessary as well as the macros to ensure fusion to the root. However, D1.1 only covers carbon or low alloy steels that are 1/8 in [3 mm] or thicker with a minimum specified yield strength of 100 ksi [690 MPa] or less. If your unlisted material does not fall under that scope you may need to consider alternate testing. Testing for hardness is typically required when you are dealing with quenched and tempered steels such as A517. With this material you want to keep the hardness below certain levels to prevent cracking, but still need to keep the tensile strength high. This makes procedure qualification essential.