Why Welding Stainless Steel Causes Distortion

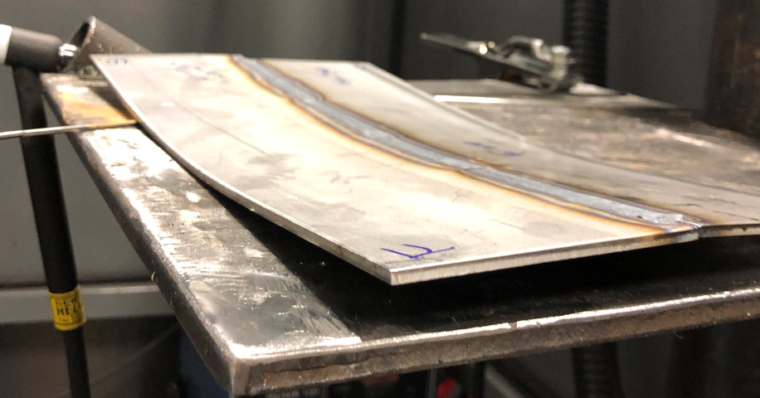

Austenitic stainless steels, renowned for their corrosion resistance and aesthetic appeal, are a staple in numerous industries. However, welding these materials often presents a significant challenge: distortion and warpage. This isn’t just a cosmetic issue; it can lead to dimensional inaccuracies, compromised functionality, and costly rework. So, why are austenitic stainless steels so prone to […]