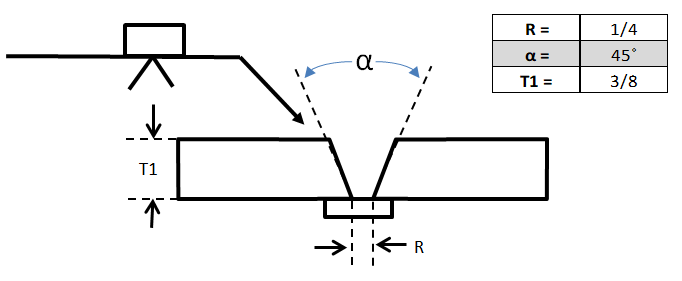

The AWS D1.1 Structural Welding Code (Steel) welder qualification plate tests consists of a groove weld with a 45-degree included angle. The plates are prepared to a knife’s edge and a ¼ in [6 mm] backing strip is used. The test for unlimited thickness will use plates that are 1 in [25 mm] thick. Anything less than that will qualify the welder for two times the thickness used in the test. Below is an example of a test that will qualify the welder to weld up to ¾ in [20 mm].

The backing bar should extend the length of the test plates or could be slightly longer to allow for a run-on and run-off tabs. It should be 1 in [25mm] wide (3 in [75 mm] wide if it will not be removed when radiographic inspection is used for evaluating weld soundness in lieu of bend tests) and ¼ in [6 mm] to 3/8 in [10mm] thick.

GET YOUR FREE UNDERCUT TROUBLESHOOTING GUIDE!

Acceptance Criteria

In order for the welder to successfully pass this test, he or she must pass both visual inspection and meet the weld soundness acceptance criteria. Soundness is tested by performing bend tests or by radiographic inspection.

In order to pass visual inspection the weld must:

- Have no cracks of any size

- Craters must be filled to the full cross section of the weld

- The weld must not exceed 1/8 in [3mm] reinforcement

- Undercut must not exceed 1/32 in [1mm] in depth

- Additional requirements apply for tests that have an open root (no backing)

In order to pass weld soundness by bend tests the specimens must:

- Be bent according to the specifications of the code (different bend radii are specified depending on the base metals yield strength).

- The bent specimens should:

- Not exhibit any discontinuities greater than 1/8 in [3mm] in length

- Have no discontinuities greater than 1/32 in [1 mm] in length that combined add up to a total of more than 3/8 in [10mm]. Any single discontinuity exceeding 1/8 in [3 mm] constitutes a failure as seen in “a” above.

- Corner cracks should not exceed ¼ in [6 mm] in length. If the crack is a result of slag inclusion then the maximum length cannot exceed 1/8 in [3 mm]. If a corner crack with no evidence of slag inclusion is present and exceeds ¼ in [6 mm] in length the test specimen is discarded and new specimen cut from the original test plate must be tested. Corner cracks may be the result of poorly prepared tests specimens.

3. As stated previously, radiographic testing may be used in lieu of bend tests. Procedures, technique and acceptance

criteria for this type of test is provided in Clause 8 (Inspection) of AWS D1.1/D1.1M:2020 Structural Welding Code – Steel (Clause 6 if you are still using the 2015 edition).

Welding Positions Qualified

It is sometimes incorrectly assume that the 1G test described above qualifies the welder for all positions. The qualified positions are based on the position used for testing. In this case, the 1G (flat) position for a plate groove weld test will qualify the welder for 1G as well as 1F and 2F (horizontal and flat fillet welds).

For additional information see Table 6.10 of your AWS D1.1 (2020) code book. It provides all the details on welding positions for welder performance qualification. Table 6.11 details the range of thickness qualified.

We administer tests on a regular basis. When working strictly as a CWI we provide no guidance when taking these tests. When we are working as consultants we provide training and provide proper instructions in order to increase the probability of a successful plate test. In next week’s article we will ex

pand on this.

References:

Qualification of Welding Procedures, Welders and Welding Operators

AWS D1.1/D1.1M:2020 Structural Welding Code – Steel

What are range of base material qualified for welder acc. to AWS D1.1 2020 if I use A36 for test coupon (Exp: SS400 – JIS standard)?

My suggestion:

Option 1: Any type of Carbon and Low alloy steel which SMYS 690 Mpa or Less (Limitation of AWS D1.1)

Option 2: any AWS D1.1 qualified base materials (such as mention on WPQR format – Annex J)

Anyhow, Pls give your advance in this case?

AWS D1.1 classifies base metals into groups. ASTM A36 is a group I base metal if it does not exceed 3/4-inch [20 mm] in thickness. If it does, it becomes a Group II. The welding procedure may be adequate for welding any group I and II base metals provided you use ASTM A36 of 1 inch [25, mm] or thicker for your PQR.

The 1G-1F flat position welding test is the easiest, however, if I may point out, a well needed test. The 1G-1F flat position test, a welder can display basic principles of welding forming solid beads using the step method he/she can then stack beads. Once he/she has mastered the 1G-1F position, it is a good tool to prepare them for the other welding positions ( ie . . 2G, 3G, 4G )

What is the minimum length and width for test coupon for unlimited thickness.

What code are you following? Also, is this for welder performance qualification or welding procedure qualification?

This will Help to better my business tremendously, Jason