Knowledge of welding symbols is not a requirement limited to welders. Many other professionals must have the ability to interpret and write welding symbols. From estimators to designers to quality personnel, this universal language must be understood.

In our last post we touched briefly on the importance of being able to interpret welding symbols. If you missed this previous post or simply did not get a chance to download your free welding symbols test you can still do so by clicking here.

This test can help you gauge your level of knowledge of welding symbols, that of your employees, or that of your students. So go and get your free copy by clicking the link below.

Welding symbols communicate vital information about the characteristics of a weld to welders, quality personnel, production supervisors, estimators and many others. Unfortunately, not many can interpret welding symbols. Believe it or not, this inability to read welding symbols can cost a fabrication company thousands if not hundreds of thousands of dollars.

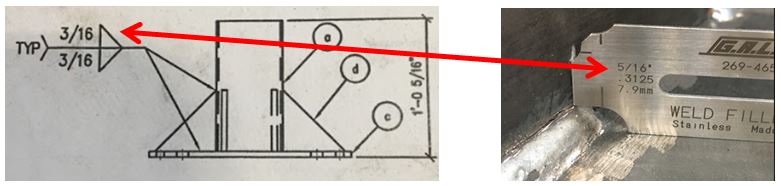

We are all aware that overwelding can add significant costs to welding operations. If you need to get a feel for how much simply read Cost of Overwelding.

We help customers on a daily basis reduce their manufacturing costs. Eliminating overwelding is one of the easiest ways to accomplish this. The lack of understanding of welding symbols plays a huge role in increased welding costs in two ways:

- Welding symbols appear in shop drawings but welders don’t follow them due to lack of training on how to interpret welding symbols.

- Welding symbols are not specified leaving welders to use their best judgement as to the size of the weld. This instance typically means the engineering department does not have knowledge of welding symbols (or far worse, no knowledge of weld design) and assume production personnel will make a decision as to the size and other aspects of the weld.

All professional manufacturing facilities should have a sound understanding of welding symbols across the organization. Here are a few examples of those who must know how to read welding symbols and a few reasons why:

- Estimators – To properly bid on a job you must know how much welding needs to be done. This includes the amount of filler metal, shielding gas or flux, amount of welding time and additional operations such as finishing weld surfaces and total hours. Welding symbols communicate all of this or give you enough information to calculate these figures.

- Designers – Maybe you don’t build products for other companies but design your own. Design engineers should determine weld sizes based on strength requirements. Once they make these determinations they should be documented in the form of welding symbols within the part drawing to properly communicate this to those who will be making the end product.

- Inspectors – Inspectors must know how to interpret welding symbols in order to accept or reject a weld. Welding symbols also communicate required nondestructive tests, some of which will be carried out by the inspector. Certified Welding Inspectors (CWIs) are tested in their ability to read and interpret welding symbols as part of the AWS CWI examination.

- Welding Engineers – Welding engineers are typically the ones that develop welding procedures to be used in production. Being able to interpret welding symbols gives the welding engineer information needed to choose the best welding process and filler metal size. Welding engineers will understand that if a 1/8” fillet weld is being called out, a GMAW procedure using a 1/16” diameter wire is not a viable option. Welding engineers many times are also called in to help in estimating the cost of a project and will work hand in hand with the estimators.

- Welders – When we think of understanding welding symbols we immediately think about welders since they are the ones depositing the weld metal. They need to be able to interpret welding symbols. If they can’t, they will be determining the size and other characteristics of the weld based on their best judgement. The size of the weld should be an engineering decision that is not left up to the welders.

- Supervisors – Similar to inspectors, supervisors need to make sure that all specified instructions are being followed. Exceeding welding sizes have the potential to delay jobs. Welding smaller than required has the potential for premature failure and other issues.

- Consultants – Consultants and other professionals that help manufacturing facilities reduce costs and improve efficiencies must be able to interpret welding symbols. Many times they are the ones that end up doing all the welding symbols training for their customers. A competent welding consultant must also be able to look at print, examine the weld symbols and determine whether or not the weld sizes are adequate for the intended purpose.

Click the image for more information on these resources

Are you in any of the above mentioned roles? Do you need help understanding welding symbols? Then the Welding Symbols Training Manual is just what you need. This publication is designed to take those with limited or no understanding of welding symbols to a point where they can interpret 95% of all the symbols they will encounter in a production environment. If you are interested simply click here for more information.