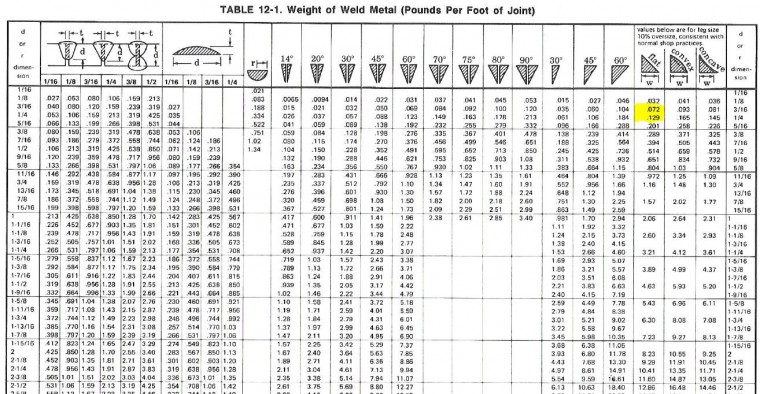

Calculating weld metal requirements seems complicated but for the majority of applications it should not be. Short of having a computer program that calculates this for you, the easiest way is to use the tables found in The Procedure Handbook of Arc Welding. Table 12-1 provides data to calculate weight of weld metal required per foot of joint. It has this information on fillet welds (which can be used for laps as well) and groove welds. All you need to know are the details of the joint (leg size, bevel angle, root, etc.). If you don’t have the tables from the Procedure Handbook you can do all these calculations relatively easily by hand. Take a look at our post on Calculating Weld Metal Requirements by Hand

We receive calls from customers inquiring about weld metal requirements for jobs they are quoting. When we speak with the customer we’ll ask for the total inches (or feet) of weld, weld type and sizes. We’ll also need to know the process being used to take into account electrode efficiency when telling them how much product to buy.

A customer recently gave us this information:

I have an assembly that has forty-five 3/16” fillet welds that are 3 inches long. It also has seventeen ¼” fillet welds that are 4.5 inches long. Per the contract we have to build 3,200 of these. How many pounds of mig wire do we need for this job?

We go to the tables on the Procedure Handbook and see that for a 3/16” fillet with a flat face we need .072 pounds of weld metal per foot of joint. We also see that for a ¼” fillet the amount needed is 0.129 pounds per foot of joint. These values include a 10% allowance for overwelding. However, please note that this is a very small allowance. If your 3/16” fillet turns out to be ¼” you are overwelding by 77%!

Table 12-1 in the Procedure Handbook of Arc Welding helps determine weld metal needs based on joint geometry.

So our totals are:

45 welds x 3in each = 135 inches = 11.25 feet -> @ 0.072 lb/ft this yields 0.81 lbs per assembly

17 welds x 4.5in each = 76.5 inches = 6.375 feet -> @ 0.129 lb/ft this yields 0.82 lbs per assembly.

Adding these together gives a total of 1.63 lb per part. And for a total of 3,200 parts we would need 5,216 pounds of weld metal. Since the process they will use is GMAW and in this case they were going to use the short circuit mode of metal transfer we look up the wire efficiency and see that it is 95%. We divide the total weld metal needed by the efficiency 5,216/0.95 and this gives us the amount of weld wire that needs to be purchase, which in this case is 5,491 pounds.

If this was a job to be done with stick electrode we would need to use an efficiency of 65% (much lower due to stub loss, slag and spatter). In this case we would need 8,024 pounds. Never forget to include the electrode efficiency or you can be in trouble.

If you do not have a table such as that in the Procedure Handbook and you need a quick answer you can always use pencil, paper and high school math to get this information. Take a look at our post on how to do so: Calculating Weld Metal Requirements by Hand

Hi please could you provide me handbook about pipe welding calculator pdf

We do not have an online calculator, but you can learn to estimate weld volume requirements for groove welds (pipe joints) by reading: Calculating Weight of Weld Metal Required.

Can we find this table in ASTM standard

The table is in the Procedure Handbook for Arc Welding. The link to it is in the post.

Can we find this table in ASTM standard?

HOW MANY POUNDS OF 1/8 WIRE WILL IT TAKE TO WELD OUT A 65″ SCHEDULE 40 PIPE?

Can you provide the joint details? Is it a 75 degree included angle? What is the dimension of the root opening?

253MA 1/8″ rods. How many square inches of weld per pound.

Can you please clarify your question? Are you asking how many inches of 1/8″ rod per pound of weld? If so we need to know the weld type and weld size.

way to much heat you would get the same result with a cnstinsaot weld with the right aperage your machine should have the right settings what happens when your weld is to hot it gets brittle think of steel when you have cold roll steel you can work with it , it can bend and be worked.. hot roll steel is like what you are doing is like glass sort of it is weaker and can shatter a good weld is a good weld and your method has way to much penentration just my advice i weld all day long