Stress relieving is a form of post weld heat treatment. In stress relieving we heat a material to a specific temperature; hold it at this temperature for a specified amount of time in order to reduce or eliminate residual stresses; and then cool it at a slow enough rate to prevent these stresses from redeveloping.

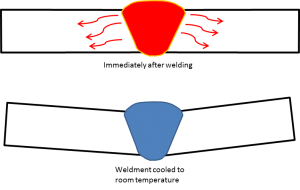

In most cases, stress relieving is done to regain dimensional tolerance and to reduce distortion. Distortion occurs due to the rapid and uneven heating and cooling of the weld metal and the surrounding base metal. As the molten weld metal cools it contracts and does so at a different rate than the base metal around it.

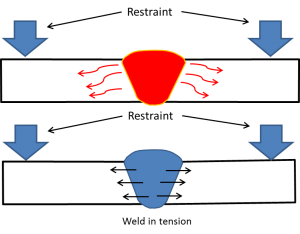

When this happens, if the part is restrained we will have residual stresses. Essentially the weld will be in tension. If the part is not restrained we will end up with distortion. More often than not you will have a combination of both.

Distortion occurs due to the non-uniform heating and cooling of the weld metal and the surrounding base metal

As the image above shows, in the case of a butt joint, as the weld cools it shrinks and pulls the adjacent base material towards the center of the weld. It pulls the top closer because there is more weld metal towards to the top of the joint. If the weld was made from the bottom the angular distortion would be in the opposite direction.

In this particular case we have low residual stresses since the base metal was free to move and accommodate the contraction of the weld as it cooled.

When the part is restrained and the adjacent base metal is not free to move, we end up with residual stresses as can be seen below.

Residual stress form as a result of the weld contracting and the base material not being free to move

The members being joined may be restrained by clamps. They may be restrained by having their opposite ends welded to other members. They may be restrained by the joint configuration such as a circumferential joint as the one seen when welding pipe. The restraint may also come from the sheer mass of the part such as those seen in jumbo shape components.

When the base metal adjacent to the weld is not free to move something has to give. That something is the weld. The restrained pieces are essentially trying to tear the weld in half by pulling on it from opposite directions. This creates a situation where the weld remainsunder a tensile load. This is residual stress. Residual stresses are typically of the same magnitude as the yield strength of the base material. They are not desired because they can cause premature failure of manufactured products. They also reduce the load capacity of welded connections. Residual stresses can also speed up the damage caused by fatigue and creep.

We stress relieve to reduce residual stresses. By uniformly heating the part to the stress relieving temperature and holding it for a specified amount of time, we allow the residual stress to be lowered.

The temperature to which we heat a part for stress relieving must be below the material’s transformation temperature. For ferritic steels, this transformation temperature is around 1350˚F [730˚C]. For most steels, the stress relieving temperature will be around 1100-1200˚F [600 – 650˚C]. Certain steels may require higher temperatures.

One very important aspect of stress relieving that is often times missed is that the weld must be allowed to cool down to room temperature before stress relieving. If the weld is not allowed to cool and we perform stress relieving we will end up with the residual stresses we were trying to avoid.

Once the part is cooled to room temperature, stress relieving can begin by heating the part uniformly. The heating rate must not exceed 400˚F per hour, but in most cases it will be slower.

Holding times are typically calculated by the thickness of the material. One hour at the holding temperature per inch [25mm] of thickness of the thickest member being joined.

The part must then be cooled uniformly at a controlled rate to avoid residual stress from returning. Cooling rates are dictated by codes or other specifications. Typically we do not want to exceed a cooling rate of 400˚F [205˚C] per hour. To achieve this slow rate of cooling the part must be allowed to cool in the furnace. Once the part reaches 600˚F [315˚C] it can be cooled down to room temperature in air.

Always consult the code you are working with for specific instructions on how to stress relieve the materials you are working with.

References:

Welding Procedure Development for Non Welding Engineers

If PWHT is performed while the weldment is hot and Stress Relieving is done when it reaches room temperature, does Stress Relieving risk HIC? Or is Stress Relieving performed after PWHT?

Stress relieving is a form of Post Weld Heat Treatment. So is a “bake out” which is used to allow hydrogen to be released from the weld and prevent HIC. If PWHT is done with the purpose of relieving stress then the part must be allowed to cool to room temperature first. When using post heat to eliminate the possibility of hydrogen-induced cracking The temperatures used for stress relieving and a hydrogen bakeout are quite different as well.

The weld should not be allowed to cool to room temperature before post heating. HIC will occur once the material temperature drops below 200F. Before this happens the part must be heated to a specific temperature and held for a specific amount of time which depends on the material type and thickness. This allows hydrogen to diffuse out of the weld and prevent cold cracking upon reaching room temperature.

Codes and standards will specify temperatures and holding times. In general, you must heat the part high enough to allow hydrogen to diffuse out of the weld and HAZ but not high enough to create any type of microstructural change. Typically, this bake out procedure is done between 300˚F – 600˚F [149˚C – 316˚C]. This temperature is held for at least 1 hour per inch [25mm] of material thickness. Always consult the code you are working with or the engineer in charge before developing your own post heating procedure.

For more information read: https://weldinganswers.com/what-is-post-weld-heat-treatment-pwht/

Thanks so much! Articles like this are invaluable as I am teaching new design engineers and support staff about fabrication! It is sometimes tough to convince folks that things they can’t see are REAL and necessary, even though they add more time and money to a project.

Have a fabulous week! Sue Jokela, Metallurgical/Material Science Engineer.

Can we add a link to our website? https://www.veqter.co.uk/

This may provide some useful information for your readers on residual stress measurement.

Hello Ian, thanks for your comment. We will email you to find ways to collaborate.

can we do stress relieving again on same welded steel assembly

Can you please be more specific? Are you asking if we can do stress relief twice? Do you mean weld, stress relieve, weld again and stress relieve again? Or stress relieve two times in a row without welding in between?

Dear sir,

Please let me know the purpose of thermocouple (on diff- diff location on the assembly to be stress relief) , while subjecting the job in stress relief process in Furnace.

Thermocouple may be used for different purposes but mainly they take temperature readings. If they are being placed in different placed in the welded assembly it may be ensure the entire structure reaches and maintains the desired temperature.

Thank you.

I find it helpful when you said that the welded material must be cooled down to room temperature before subjecting it to the stress relief process. My dad is thinking of contacting a pipe weld stress relied service for the material he has been working on for quiet some time now. I’ll share this article with him later so he would be informed about the process. Thanks a lot!

You are very welcome!