In today’s article we’ll be discussing a critical aspect of welding which is crucial in ensuring the safety and long useful life of structures. When engineers conduct a fitness for service analysis of structures they are looking for flaws. These flaws may be cracks, loose bolts, deformations, rust damage (thinning of structural members) and other problems that present a threat to the integrity of said structure.

The intent of this fitness for service analysis is to determine which of the follow three actions should be taken:

- Replace the entire or a portion of the structure

- Repair the flaw

- Do nothing

Now you may be asking yourself, if we find a crack on a structure, say on a bridge, why would we do nothing? Why wouldn’t we always repair a crack knowing how dangerous cracks can be? At least in welding, right? This brings us to the marvelous field of Fracture Mechanics.

Fracture Mechanics is a method of characterizing the fracture behavior of sharply notched structural members (think a crack or a flaw) in terms that can be used by the engineer performing a fitness for service analysis. Fracture mechanics is based on analyzing the stresses around a notch or a crack.

Conducting this type of analysis may lead to the conclusion that a crack or other flaw does not pose an immediate threat to the integrity of the structure. That may be because the stresses around that crack or flaw are of a magnitude that would not cause it to grow to a critical length before the next fitness for service analysis is conducted.

To understand why we may choose not to fix a crack on a bridge or other structure we need to understand the three stages of fatigue fracture:

- Crack initiation

- Crack propagation

- Final failure (brittle fracture)

Crack Initiation

Assuming that the fabrication and erection processes occurred without problems we start with a structure with no defects. However, over time and under cyclic loading certain defects may develop. These defects start at the microscopic level which are invisible to the naked eye. This makes detection a challenge. These types of defects are unavoidable and thus the reason why frequent inspection of structures is necessary.

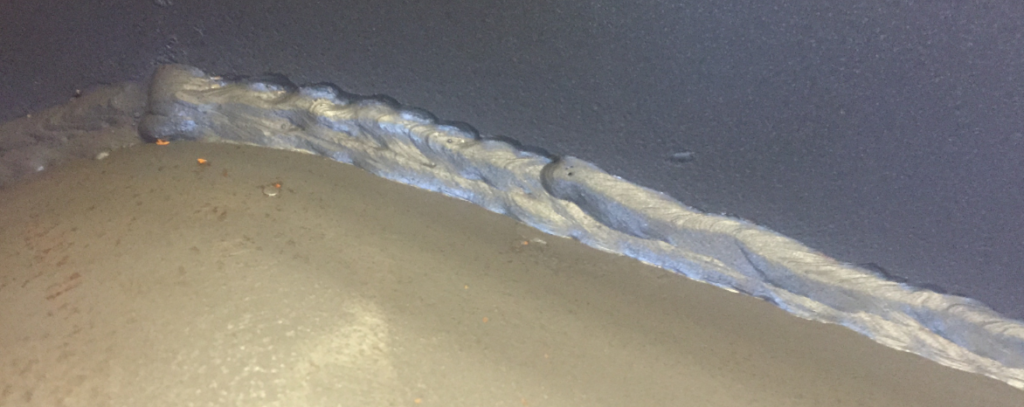

Fabricating defects, for example undercut in welding, can facilitate the initiation of crack since it creates a stress riser. But even without defects at the start, structures will develop cracks and other flaws under regular use. Whether it is from a fabricating defect, from normal use or a combination of both, this represents the crack initiation stage.

Crack Propagation

Once a crack initiates, it will be more susceptible to the damaging effects of cyclic (fatigue) loading. The crack will begin to grow in what is called the crack propagation stage. This stage is characterized by a very gradual growth of the flaw. Factors like material properties, stress levels and the number of load cycles play a role in determining the rate at which the crack will grow.

Through proper analysis and the use of engineering principles a fitness for service engineer can predict the growth rate of the crack. This is very useful information because the engineer should already know at what point the crack will reach a critical length. The critical length of a crack is the point at which the uncracked portion of the structural member is no longer able to carry the load and fracture occurs.

Final Failure

As stated above, once a crack reaches its critical length, fracture occurs. We refer to this stage also as brittle fracture. Crack propagation may be slow and may take months or even years to grow to a critical size. However, once the critical size is reached, the crack will grow at speeds of up to 7,000 feet per second [2134 m/s] resulting in catastrophic failure.

Many times it was believed that a catastrophic failure occurred without warning. However, oftentimes there were plenty of warnings, they simply were not noticed.

Now that you understand the three stages of fatigue fracture you should be realizing how important a quality control system is in welding operations. You also understand the importance of inspection and of the certified welding inspector (CWI). You may not like CWIs because they are too stringent, now you know why they are that way. Even undercut at the toe of a weld can initiate a crack and lead to fracture.

Not all defects lead to catastrophic failure, but at the very least they lead to property damage, lost time, costly repairs and upset customers and/or users.

Understanding the fracture mechanism should lead fabricators into taking proactive and preventive measures. These measures seek to:

- Improve weld quality to avoid discontinuities which may cause crack initiation

- Extend the lifespan of a structure by addressing flaws such as cracks at an early stage (inspection)

- Prioritize safety by minimizing the risk of failures

- Train welders, inspectors and other quality personnel in the areas of weld quality and inspection (welders are the first line of defense and thus our most important inspectors)

Have you been part of a failure analysis where brittle fracture occurred due to a welding or other fabrication defect? What were the lessons learned?

Reference:

Weld Troubleshooting for Non-Welding Engineers

Is welding P1 to P15E possible?

They can be welded together but that does not mean you should. In ASME applications there typically is a transition material between the two. Also, they are for quite different service conditions so it is not often that there is a need to have both welded. A design engineer should specify the transition metal as well as the appropriate filler metal. There may be limitation as to the transitiion metal lenght (there may be a mininum distance between welds).