If you have welded aluminum you know that it behaves considerably different than steel. Other than the strength difference and general appearance, there are four physical characteristics of aluminum that make it weld completely different than steel. These are:

- High thermal conductivity

- High solidification shrinkage

- High hydrogen solubility

- Oxide coating

Aluminum can be successfully welded, but a thorough understanding of its physical characteristics is a must.

When welding aluminum it is very important to understand how these characteristics affect weldability. Weldability does not simply mean that a metal can be welded, but rather the ability to weld it defect free. A complete understanding of aluminum’s physical characteristics will allow you to troubleshoot issues with ease and generate a solution in a timely manner. So, without further ado here are these 4 characteristics explained.

- High Thermal Conductivity

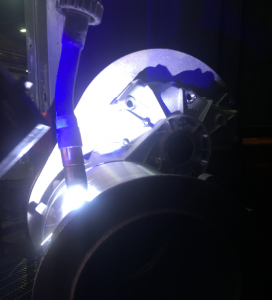

Due to its high thermal conductivity, aluminum dissipates heat quite rapidly. This is why it is a great material for radiators. In welding that can create challenges. Higher welding current are needed to assure fusion which means heavier duty equipment must be used. If you have ever welded really thick aluminum with GTAW, you probably noticed that you have to wait a while after starting the arc for the puddle to be ready to add the filler. This is due to the heat being transferred away from the weld area very quickly. Once the part comes up in temperature you can finally get that puddle started and you can start adding filler.

You can also see evidence of high thermal conductivity at the start of your GMAW aluminum welds. They will tend to be ropey and show clear signs of lack of fusion or cold lap. Even with hot start features on welding equipment this will always be an issue with GMAW aluminum welds.

- High Coefficient of Thermal Expansion

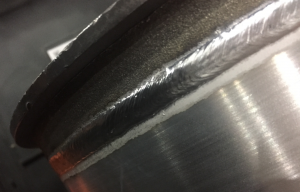

Aluminum shrinks about twice as much as steel during solidification due to its high coefficient of thermal expansion. This creates a couple of problems: higher buildup of residual stresses around the weld and greater distortion. Care must be taken with weld terminations as this high solidification is responsible for crater cracks. If a crater forms at the end of an aluminum weld, it can develop into a longitudinal crack. A big mistake is assuming that you can simply weld over it with a second pass and take care of it. This does not work.

In GMAW there are two common solutions for crater cracks. The first is to use a back step technique (when you get to the end of the weld reverse direction for at least 1 to 2 inches). The other option is to utilize the crater function if the welding equipment has that feature.

Crater cracks are not that much of an issue in GTAW simply because the operator has the ability to feather the end of the weld to minimize the crater size or eliminate it altogether.

- High Hydrogen Solubility

Aluminum in its molten state has very high hydrogen solubility. Hydrogen comes from contaminants in the base material such as oil and grease (hydrocarbons), water vapor that breaks down in the arc, condensation on the filler metal, wire drawing lube residue on filler metal, extremely high humidity, breezes, water leaks in welding equipment, shielding gases and hydrated oxides among many other sources.

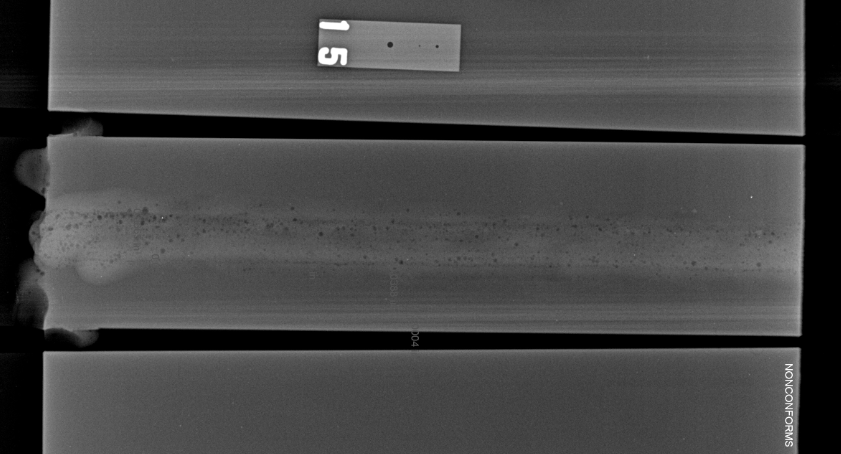

X-ray of an aluminum groove weld test. The surface showed no porosity. The dark spots are voids (porosity) and show up dark due to being lower density areas.

If you take a look at acceptance criteria for RT (x-ray) in AWS D1.2 (Structural Aluminum Welding Code) and compare it to AWS D1.1 (Structural Steel Welding Code) you will notice that there is a much greater allowance for porosity in AWS D1.2. It is not impossible to get a porosity free weld, but it is extremely difficult. Most of the porosity will be sub-surface.

- Oxide Coating

As soon as aluminum comes in contact with air it combines with oxygen to form a very thin, but very tenacious, oxide layer. This oxide layer is desired because it provides corrosion resistance; however, it can make welding a bit challenging. This aluminum-oxide layer is very porous and traps moisture, grease, oil and other contaminants.

It is recommended that thick oxide layers be removed prior to welding. This can be done via mechanical means (i.e. using a stainless steel brush or stainless steel wire wheel). We also need to remove oil, great or other surface contaminants. Using acetone is a good way to do this. When the oxide coating is very thin the arc energy is sometimes sufficient to clean it.

This article covered some of the major challenges in welding aluminum. It is important to seek assistance when developing a welding procedure if you are not familiar with aluminum metallurgy. Filler metal selection is critical. Picking the wrong alloy can make some inherent aluminum welding problems much worse. 4043 and 5356 are the most commonly used aluminum filler alloys, but they are not the only ones. Call an expert if you need help selecting the right filler metal. Always have details of your application including: base alloy, mechanical requirements, service temperature, thickness, etc. Avoid problems, seek assistance when necessary.

Reference Material: Welding Metallurgy and Weldability by John C. Lippold

We purchased an aluminum cabinet that the manufacturer used to weld a door to the one side of the cabinet. Before installation and during the loading/unloading there was a small hit to the door, so 2 horizontal long cracks, exactly from the middle of weld zone, appears. Were they cold brittle cracks? If so, why the cold brittle cracks appear? How can we claim the manufacturer? because they said this cracks appeared after the hit! (but usually metals be damaged affected a hit not be cracking.)

I will reach out to you via email. The more information we have the easier it is to determine the root cause or at least possible causes. Pictures would be great. I’ll email you a list of information needed.

I never knew that aluminum is perfect for making a radiator because it disperses heat quickly. This would help my uncle create a durable radiator for the car that he is creating for his son. He loves inventing things, which is why he thought about constructing a rideable toy car for his son. I will share this information with him when he visits us tomorrow. Thanks!

Let us know how the car turns out!

Hi Sir. I use special purpose machine with gmaw (mechanized) to weld a T joint of spud with base tank of 2mm thick MS sheet. I get a pin hole at the start position of the weld when the weld overlaps the start position before completion or stopping. I use 90/10 ACM. Welding at 230 to 250A and 26V. 1.2mm AT 70S-6 wire. Can you please suggest a solution for this?

Hello Raj. The pinhole you are seeing could be porosity or simply a crater pinhole. If it is porosity you are probably getting starting porosity (visible or internal) and when you overlap the porosity comes up to the surface of the bead. If this is the case your starting porosity may be caused by several things. Check each one of these:

1. If you get a gas surge (very commeon on bulk gas delivery systems) your flow rate may approach 200 CFH and create a venturi effect which drives air (hydrgron) into the weld pool at the start of the weld. If you welder has the option to set a preflow set it for about 0.2 seconds.

2. Make sure you contact tip to work distance is not excessive at the start to ensure proper gas coverage. At 230-250 amps with a 1.2mm wire you should be at no more than 25mm contact-tip-to-work distance.

3. Check the base material for surface contaminants (rust, mill scale, paint, oil)

4. Check for air drafts that may be blowing the shiedling gas away (fans, open doors, etc.)

5. Erratic arc starts can also cause starting porosity (check work lead connection).

If the pinhole at the overlap is due to crater formation simply backstep 20-40mm. Get to the end of the weld and then reverse direction for 20-40mm and the crater (and pinhole) will be filled.

What are the challenges fa ing Aluminium alloy 4043? Your response is important

There are many challenges. Take a look at this article for more details: https://weldinganswers.com/4043-v-5356-aluminum-filler/