Tag Archives: Shielding gas

Welding Procedure Development: Qualification

What Causes Welding Spatter

17 reasons why you are getting spatter in your welding operations

Spatter is present in welding. It’s all over welding. But it doesn’t have to be. Spatter costs fabricators millions of dollars every year. Its removal constitutes rework that significantly and negatively impacts productivity. Many fabricators work under the assumption that spatter is a necessary evil, a part of welding. However, this couldn’t be further from […]

7 Reasons to Consider Stick Welding Over Other Processes

Shielded metal arc welding (SMAW), or what is commonly referred to as “stick welding,” is one of the oldest welding processes. Despite being one of the first welding processes developed, it remains one of the most used welding process worldwide. If you have been working in a fabrication shop for years using advanced GMAW (mig) […]

Danger of Using the Wrong Shielding Gas for GMAW

In our previous article we mentioned that a customer was inquiring about running their 98% argon / 2% carbon dioxide (98/2) shielding gas on mild steel. This gas is used on stainless as it maintains the amount of reactive gas (in this case CO2) under 3%. Our quick answer was “yes, you can weld carbon […]

Which is the best shielding gas for MIG welding?

Today we received two different requests for help pertaining to shielding gas selection. The first caller requested a chart that tells them what materials can be welded with the different shielding gases that they had. They wanted a chart that can be provided to the welders to make sure they used the right gas on […]

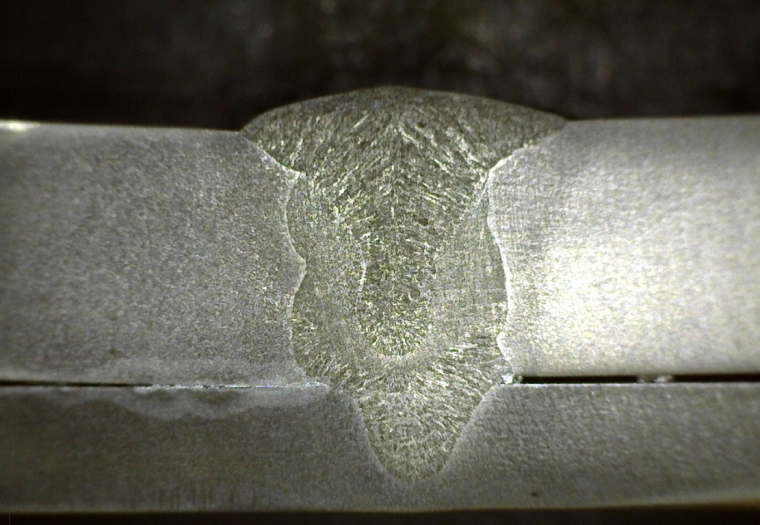

7 Variables That Affect Weld Penetration

Getting deeper penetration, or at least adequate penetration is very important in welding. There are a few applications in which we wish to minimize penetration, but in general we always want good penetration. There are many variables that affect penetration, some more than others. It is important to know how each individual variable affects the […]

5 Factors that Contribute to Silicon Island Formation in Welds

The formation of silicon islands on welds made with the GMAW (mig) and MCAW (metalcore) processes is very common. For the most part, these silicon islands are not a problem. However, if the weld is to be painted, you better remove these islands. Otherwise, they will eventually pop off and leave an unpainted spot in […]

Is Weld Strength Affected by Shielding Gas Mix?

Can our selection of shielding gas affect the strength of a weld and other important mechanical properties? Absolutely! The difference is more pronounced when using flux-cored (FCAW) wires than when using mig (GMAW) wires, especially as the wire’s tensile strength goes up. Although we can affect strength by using different gases, what we should be […]

Control Your Shielding Gas Usage

If you own or run a business in which welding is an integral part of the manufacturing process you know one of your recurrent expenses is your shielding gas. Very few manufacturing facilities, big or small, have excellent control of gas usage. Most end up using twice as much than necessary, and in some cases […]