In a perfect world parts would fit together perfectly every time. However, as we all know, this isn’t the case. We mostly think of poor fit up as something that annoys welders but which they can compensate for. But the reality is it can have tremendous impact on your bottom line. Or, in many cases, compromises the integrity of the welded connection.

Poor fit up can be caused by poor workmanship, by parts not cut to the right dimension,by distortion during welding, by volumetric changes during heating and cooling, by improper or lack of fixturing, and by several other reasons. If you have bad fit up in your shop it is worth your time to investigate how to fix it. Or at least minimize it. Below is an explanation as to why you should be concerned about fit up from a structural integrity standpoint.

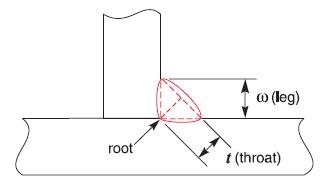

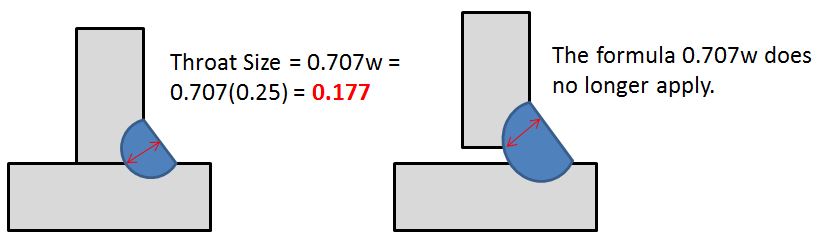

The strength of a weld is determined by its length and by the size of its throat. There is a difference between theoretical throat, effective throat and actual throat, but for now, we’ll call the throat the distance from the face of the weld to point of deepest root penetration.

Weld sizes are determined on the design phase. Much time is spent sizing welds to ensure that they can effectively transfer loads. In the case of a fillet weld, if you have a gap between both plates you will have to increase the size of your fillet weld by the size of the gap in order to get approximately the same throat size and thus the same strength. If you don’t know the size of your welds get a weld gauge – using weld gauges is easy, but if you need instruction go to Proper Use of Weld Gages.

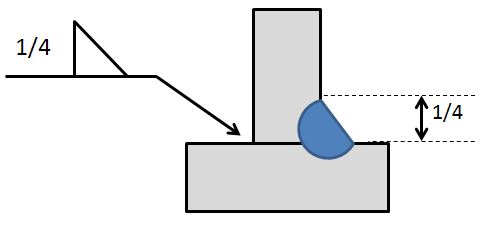

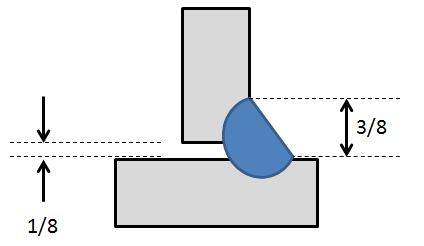

As you can see below, if a ¼” fillet is needed but there is a gap of 1/8” the new fillet size must be 3/8” in order to achieve the same strength.

The reason we need to overweld this way is because our throat is measured from the face of the weld to the point of deepest penetration at the root. The diagram below illustrates that this two welds, although significantly different in size, provide the same strength which as explained earlier is directly proportional to the dimension of the throat.

The double arrow indicates the throat. As you can see it’s about the same by increasing the weld size from 1/4″ to 3/8″.

OK, so what’s the big deal? The big deal is that a gap of just 1/8” can potentially cost you thousands of dollars. The leg size of your fillet weld went from ¼” to 3/8”. That’s just a 1/8” increment which does not seem like much. But do you know that is a 124% increase in weld metal volume? Yes, you read that correctly, that is a 124% increase in weld metal volume.

If you are not increasing your weld size as shown the throat of the weld would be reduced significantly and so would the strength of the weld. This may be enough to cause the welded connection to fail and may lead to costly warranty work, possible litigation and loss of contracts.

So the right thing to do is to adjust your weld size. If your fit up is consistently bad, costs will increase rapidly. The example below will illustrate this point.

Let’s say you have 120 inches of weld per part out of which 60 have this kind of bad fit up. Let’s see the difference in weld volume between these two:

Volume of 60 inches of weld on a 1/4” fillet = Cross Sectional Area x Length = 0.0313 x 60 = 1.878 cubic inches. Using the density of steel this volume equates to 0.53 pounds of weld metal

Volume of 60 inches of weld on a 3/8” fillet = Cross Sectional Area x Length = 0.0703 x 60 = 4.218 cubic inches. Using the density of steel this volume equates to 1.19 pounds of weld metal. As you can see, 124% more filler metal needed.

If you are building 100 parts per day, that bad fit up adds to (1.19 – 0.53) x 100 = 66 pound of additional weld metal needed per day. Over a year (250 working days) that’s 16,500 pounds! If you are paying $2 per pound of wire you are wasting $33,000. But that’s not all, it gets worse…

You are still welding at the same speed, since your deposition rate doesn’t change unless you change your WPSs. So to deposit more than double the amount of wire will cost you dearly in terms of labor.

Assuming a 6.5 pound per hour deposition rate, it would take you an additional 2,538 hours to weld those additional 16,500 pounds. And if your labor and overhead rate is $40/hr that adds up to $101,520!!! OUCH!!!! Or, if you do not increase the weld size and have a connection fail due to insufficient throat (weld carrying capacity is too low) you could end up spending even more.

At this point you know how much bad fit up could be costing you. So correcting the issue may necessitate and expense, but it may be well worth it and provide a very attractive payback period.

If you are overwelding, not due to gaps and bad fit up, but simply because you don’t have weld sizes specified for your welders you may want to check our article on Cost of Overwelding.

Reference: Welding Innovation Journal, Vol. XV, No.1, 1998 – Dr. Duane Miller

Excellent and concise….!!!!, as all your contents.

Thank you Gonzalo!

Wonderfully explained the cost of poor fitup

Thanks for the comment Nimesh. Glad to have you as a reader.