In our previous post we discussed categorizing cracks based on when they occur. If you missed this you can read it at Understanding Why Welds Crack: Timing. As discussed in this previous article, cracks can and should be categorized based on three criteria:

- Timing – did the crack occur immediately after welding (hot crack), did occur after the weld and base metal cooled down (cold crack), or did occur days, weeks or months later while in service.

- Direction – is the crack longitudinal or transverse?

- Location – where did the crack occur (i.e. root, toe, centerline, underbead, etc.)?

The direction of the crack can tell us quite a bit about its root cause. The direction can be longitudinal or transverse.

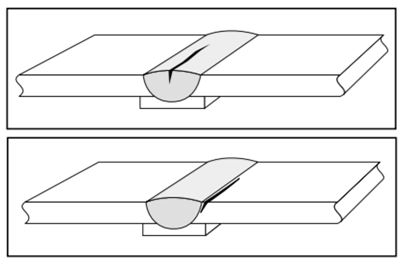

Longitudinal cracks are the most common by far in welded connections. These cracks occur and progress in the direction of travel, meaning they are parallel to the weld. They are not always a straight line as in the case of solidification cracks. They can have a step patter or an erratic pattern. They can be in the weld metal or the heat affected zone (HAZ) as shown below.

Transverse cracks are those that occur in a direction perpendicular to the weld. Transverse cracks are also called cross check cracks and happen primarily for one reason: the weld metal significantly overmatches the strength of the base metal. When the weld metal cools it shrinks longitudinally. The base material will resist this longitudinal shrinkage by going into compression. This creates high residual longitudinal stress on the weld which then promotes cracking in the transverse direction as a mechanism for the weld to stress relieve itself.

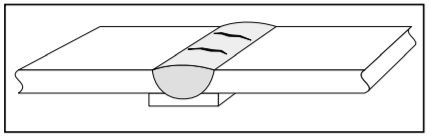

Transverse cracks are common in some hardfacing applications. These stress relieving cracks are desired because they eliminate residual stresses. Because of the application, which is surfacing rather than joining, once this cracks occur they will not expand into the base metal as the longitudinal stresses are gone after cracking.

Transverse cracking or cross check cracking is normal and desirable in some hardfacing applications.

However, if you are joining two or more members and you experience transverse cracking you should do a thorough examination. Hydrogen may facility transverse cracks. In this case the cracks are caused by a susceptible microstructure, a high level of restraint and a threshold level of hydrogen. If on top of all of that the filler metal overmatches the strength of the base metal the cracks will probably occur in the transverse direction.

Always keep in mind that the vast majority of transverse cracks occur due to overmatching the strength of the base metal with your filler metal. So when you are trying to determine the root cause of transverse cracks ask these three questions:

- Does the filler metal overmatch the base metal?

- Is the application susceptible to Hydrogen Induced Cracking?

- Is the application joining two or more members or is it a hardfacing (surfacing) application?

Based on the answers to these questions you may determine that cracking was due to overmatching and a filler metal of lower tensile strength must be used. You may also determine that the cracking was facilitated by the presence of hydrogen and low-hydrogen practice must be used. Finally, you may determine that the transverse cracks are good for relieving the stress in hardfacing applications and are perfectly OK.

As you can see, very few things cause transverse cracks and are relatively easy to troubleshoot.

Longitudinal cracks account for 90%+ of cracking and have a plethora of factors which cause them.

The next article will cover categorizing the cracks based on location. Once we understand the potential causes of cracks based on their location, we can add it to our knowledge of causes for cracks based on timing and direction and create a comprehensive weld crack troubleshooting guide.

Reference: Steel Design Guide 21: Welded Connections – A Primer for Engineers

Please note: I reserve the right to delete comments that are offensive or off-topic.