Distortion is a nasty problem we experience in welding. Understanding what causes distortion is important in order to be able to minimize or eliminate it completely. There are physical and mechanical properties that affect distortion susceptibility of materials. To learn more about this you can read 4 Material Properties That Affect Distortion.

As fabricators we hardly ever get to pick the base material of the welded structure. However, regardless of a material’s mechanical and physical properties, we can follow a set of rules to minimize or eliminate distortion altogether. Follow these steps and you’ll be on your way to controlling weldment distortion.

-

- Don’t overweld – the more weld metal we put in the joint the higher the forces causing shrinkage. Don’t lay a 5/16” fillet when a ¼” fillet will do. If there is a drawing calling out welds stick to the sized called for. If necessary, invest in weld gages. You can learn how to use them in Proper Use of Weld Gages.

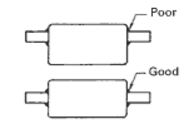

- Use intermittent welding – using intermittent welds rather than continuous welds, where design allows it, can save as much as 75% weld metal and significantly reduce shrinkage and distortion. Welding stiffeners to plate is a great place to do this.

- Minimize the number of weld passes – the shrinkage caused by each pass is cumulative, thus making it better to fill the same volume in fewer passes, especially when we are welding in the transverse distortion.

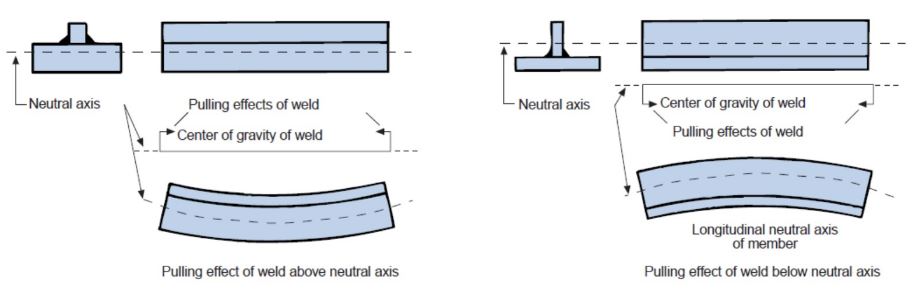

4. Weld near the neutral axis – as you can see in the image below the location of the weld relative to the neutral axis will determine which way the structure will distort. If we can place the weld right at the neutral axis we can effectively control distortion.

5. Balance welds around the neutral axis – we can’t always change the material thickness to affect where the neutral axis is. In this case, whenever possible, balance the welds around the neutral axis. This means trying to achieve symmetry.

6. Use backstep technique – this is helpful since the previous weld create a restraint minimizing distortion. This technique may not be feasible in all situations.

7. Preset parts to offset distortion – if we anticipate distortion and can predict which way the welded structure will bend, we can pre-bend the part so that after welding the part is straight.

There are other methods for reducing distortion such as planning the welding sequence accordingly to counteract shrinkage forces. Peening can also reduce some of the residual stresses. Preheating and other thermal methods can help as well.

Sources: The Procedure Handbook of Arc Welding, 14th Edition

Haynes International – Welding and Joining (Weld Defects)

I could like to know more about welding

minimizing distortion after welding

How about preheat. When properly applied, angular distortion and residual stress are reduced.