Continuous learning is something that is very important for both personal and professional development. This applies to all industries and to all positions. The welding industry, as many of its counterparts, is challenged with a workforce that is lacking the skills necessary to do the job. This is driven by the increased demand for welders, the extremely short supply of skilled welders and the lack of effective training programs.

Many fabricators have given up on trying to hire highly skilled welders. They are now choosing to hire workers that have the desire and aptitude to learn and placing them on training programs with certified instructors. These fabricators take charge of the skills gap by instituting their own training program which allows them to tailor the welders’ future skills and abilities to their particular needs.

If you are looking to create a training program a great place to start would be guide EG2.0:2017 published by the American Welding Society titled Guide for the Training of Welding Personnel: Level 1 – Entry Welder. This guide provides a framework for setting up an effective welder training program.

As stated in the foreword of this guide “welding has become a very sophisticated and technical science, requiring not only mental application but also hands-on abilities. The future need for competent welders should prompt the establishment of a greater number of educational programs. Thus, it becomes imperative that training adequately prepares individuals for industrial assignments at various levels of skill development.”

Although this guide is geared towards educational institutions, it can be applied by fabricators by only focusing on what is relevant to their operations.

The vast majority of the customers we work with don’t have a formal training program for new welders. They simply have them work with an experienced welder for a day or two and then they’re off on their own. This, unfortunately, is not proper training. Moreover, if the welder doing the training is not a good instructor or provides only tribal knowledge rather than adequate welding theory and applicability to the job, the new welder will not be set up for success.

The publication mentioned above suggest two different guidelines for implementation:

- A comprehensive program (covering all arc welding and cutting processes)

- A modular program (covering only specific processes)

Not many fabricators use all welding processes, so most would be better suited following the modular program.

A basic framework for a modular program would be as follows.

- Occupational Orientation – from preparing time cards and records to performing housekeeping duties. These may seem basic, but it provides structure and proper reporting within welding operations.

- Safety – safety should be the most important aspect of onboarding new welders. Complacency in welding operations leads to a large number of accidents and lost time incidents.

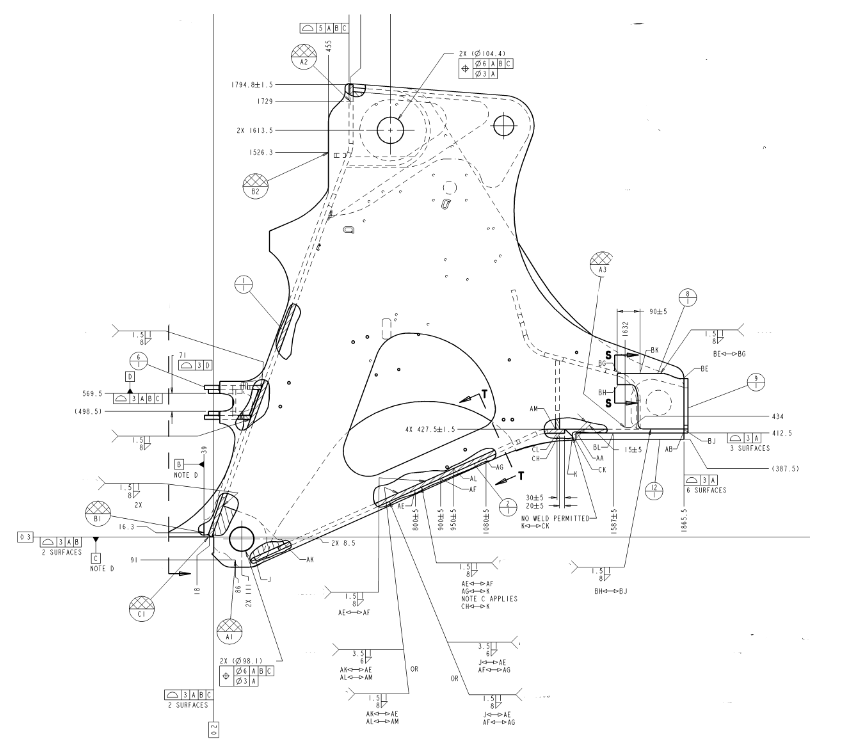

- Drawing and Welding Symbols Interpretation – the interpretation of drawings is an absolute must for every welder. Being able to use a tape measure and following a drawing to properly assemble a structure is essentially. Equally as important is the ability to read and interpret welding symbols. Welding symbols are the universal language used to convey critical information about welding requirements from the design to the fabrication stage.

- Arc Welding Processes – this training is on the arc welding process or processes that are primarily used in fabrication. Most shops will have one or at most two welding processes. There is no need to train welders on SMAW if the only process used is GMAW.

- Oxyfuel Gas Cutting – oxyfuel cutting is a skill that is essential to learn. This includes everything including lighting the torch, proper safety protocols, handling and storage of oxygen and fuel gases and proper preheating and cutting.

- Plasma Arc Cutting – similar to oxyfuel cutting, plasma arc cutting is used widely and proper training on this process should be part of all onboarding training programs.

- Welding Inspection – one of the worst things you can tell a welder is that they are not welding inspectors. Not only are they welding inspectors, but they are actually the most important welding inspectors. They are able to inspect welds not only after the weld is done but also as the weld is made. They should have a sound understanding of welding discontinuities and defects. More importantly, they should be able to recognize potential problems with the weld that may not be detected by the welding inspector by only examining the weld visually.

AWS EG2.0 goes way deeper into setting up training programs. It provides clear objectives, evaluation criteria and recommended instructional activities for each of the key modules above plus others.

In our experience, the companies that take an active role in instituting, maintaining and improving formal welder training programs are the ones that have the least amount of rework and lower overall manufacturing costs. Additional benefits include better employee retention and better and safer work environments.

Reference: AWS EG2.0:2017 Guide for the Training of Welding Personnel: Level 1 – Entry Welder

Please note: I reserve the right to delete comments that are offensive or off-topic.