In our last post we explained short circuit transfer; if you missed it you can go back and read Modes of Metal Transfer: Short Circuit. In this post we’ll spend some time going over globular transfer by covering its basics as well as its advantages and limitations.

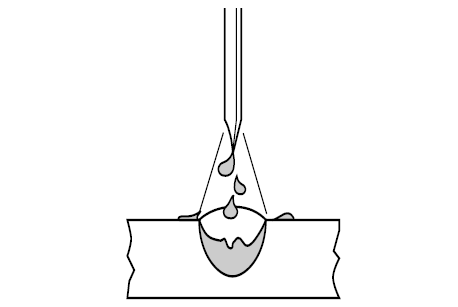

Globular transfer occurs in GMAW and MCAW processes after we exceed a certain current for a specific wire diameter. Instead of having the metal transfer via a series of shorts as in short circuit transfer, in the globular transfer method gravity pulls down on large metal droplets (globs) that form at the end of the wire due to the high currents associated with this mode.

Globular transfer produces large and irregular droplets (globs) which are pulled down towards the weld puddle by gravity.

These large and irregularly shaped droplets don’t always fall straight down. Rather, some of droplets can be expelled beyond the weld puddle resulting in large amounts of spatter. Because of the large size and large amount of energy carried by the droplets, spatter from globular transfer can fuse to the base metal making it harder to remove.

In the article in which we discussed short circuit (short arc) transfer we mentioned that the variables that determine the mode of metal transfer are: wire diameter, amperage, voltage and shielding gas composition.

The difference between globular and short circuit transfer is in the current and voltage levels. Globular uses higher currents and higher voltages. For GMAW wires the approximate current at which short circuit stops and globular transfer starts are listed below:

.023″ 90 amps

.030″ 145 amps

.035″ 180 amps

.045″ 250 amps

These numbers are approximates and there is no clear cut transition point. Instead, there will be a combination of short circuit and globular transfer for a range of amperage before the transfer becomes exclusively globular.

The shielding gas for globular transfer is typically 100% carbon dioxide and argon/carbon dioxide mixes with up to 75% argon content. If the argon content rises to about 80% or more then we would transition from short circuit into spray. We will cover spray on a later post.

Advantages of Globular Transfer

- Low cost – basic constant voltage equipment and relatively inexpensive carbon dioxide shielding gas may be used.

- High heat input permits the welding of thick sections

Limitations of Globular Transfer

- Excessive spatter adds rework (time spent removing spatter)

- Excessive spatter decreases the efficiency of the wire (wasted filler metal)

- Limited to the flat and horizontal positions due to large fluid weld puddle

- Erratic/Inconsistent arc

.

Reference: Steel Design Guide 21: Welded Connection – A Primer for Engineers

Please note: I reserve the right to delete comments that are offensive or off-topic.