Basic (Overlooked) Steps to Develop a Welding Procedure

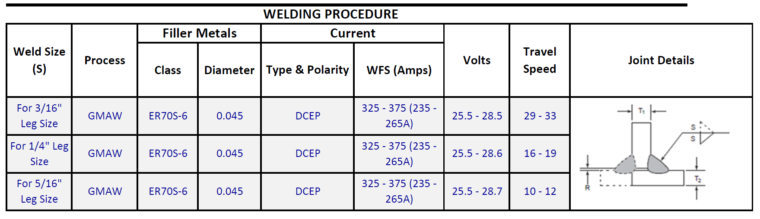

A welding procedure specification (WPS) consists of a series of welding variables and corresponding allowable ranges. The selection of these ranges is very important. The idea is that if the welder is within all acceptable ranges he or she will deposit a sound weld, provided of course that the welder has the required skill. The […]