Cracks are perhaps the only discontinuity for which there is no allowance. Most codes require that cracks be repaired. Crosscheck cracks on some hardfacing applications may be OK, but in general, if a weld cracks it’s a big problem. This problem is time consuming and costly in most cases.

When you get a crack you don’t want to just repair it and hope it does not happen again. You need to find out why the weld cracked in the first place. When dealing with carbon steel, figuring out the root cause is not always easy. However, simple failure analysis can be performed.

There are three ways to categorize cracks.

- Timing – did the crack occur immediately after welding (hot crack), did occur after the weld and base metal cooled down (cold crack), or did occur days, weeks or months later while in service.

- Direction – is the crack longitudinal or transverse?

- Location – where did the crack occur (i.e. root, toe, centerline, underbead, etc.)?

In this article we’ll focus on the first, timing of the crack.

Categorizing the crack based on the criteria above is the first action item in determining the root cause. If you know when the crack occurred, the direction of cracking and the location you can eliminate a plethora of possible causes right away. For example, if the weld cracked immediately after welding you can eliminate hydrogen induced cracking as the possible culprit.

Timing of the crack

Knowing when the crack occurred is extremely important, but not always known. Some cracks are so small that they pass inspection and are found days later while the weldment is already in service. Determining the time of the crack is crucial. If the crack occurs immediately after welding it is more than likely a solidification crack. This type of crack is also called a “hot” crack because it happens when the material is still about 200˚F. Potential causes for hot cracks in carbon steel are:

- Segregation induced cracking – caused by the presence of low melting point elements in the base metal. Sulfur, phosphorous, zinc, copper and other low melting point elements are driven to the middle of the weld nugget as it solidifies. Their low melting point means they are the last part of the weld to solidify. If present in excessive amounts, the above named elements will get trapped right in the middle of the weld and create a solidification crack. This will show up as a centerline crack (location) and it will propagate longitudinally (direction).

Top view of a centerline crack. Sometimes these cracks are barely visible to the naked eye and thus non-destructive inspection methods like liquid dye penetrant are used.

- Bead shape induced cracking – excessive width-to-depth ratio. Welds that penetrate very deep but which are narrow are also susceptible to centerline cracking by the same mechanism described above. However, when the weld is too narrow and too deep the critical amount of low melting elements that need to be present for the weld to crack are much lower.

The same way in which water in a glass freezes the weld puddle solidifies from the outside edges towards the middle. Tramp elements are sometimes caught in the middle causing cracks.

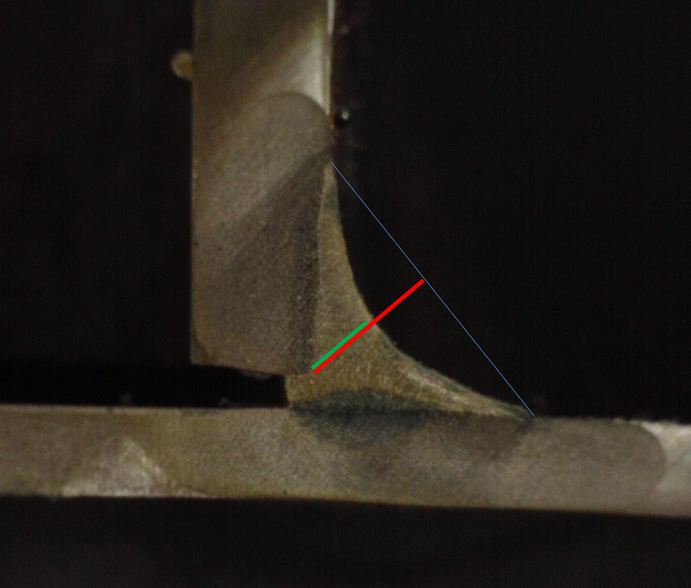

- Surface profile induced cracking – welds that are concave are susceptible to centerline cracking due to their reduced effective weld throat. Internal stresses will place the weld under tension which, with its reduced throat, may not be able to resist the stresses imposed by the adjacent base metal and crack. Conversely, if the weld is excessively convex the surface of the weld will be under compressive stress. This will usually not lead to a crack but must be avoided.

The red line represents the desired dimension of the weld throat. The weld’s concavity creates a reduction in the throat dimension represented by the green line. There is a reduction of about 50% in the load carrying capacity of this weld due to its extreme concavity.

If the crack occurs after the material has solidified and cooled down it is considered a “cold” crack. When welding steel this is typically associated with hydrogen induced cracking. It is important to note that hydrogen induced cracking is not a weld defect, rather it is a condition that will create a crack. Inspection immediately after welding will never find it. Weldments susceptible to cold cracking are required by the structural welding code (AWS D1.1) to be inspected 48 hours after welding. This allows sufficient time for trapped hydrogen to diffuse out of the weld and heat affected zone. If no cracks are present 48 hours after welding the weldment is considered good.

To learn more about the causes and remedies for this type of cold cracking read Factors Influencing Hydrogen Induced Cracking.

Many cracks that occur after the weld and heat affected zone have cooled down are not hydrogen induced cracks. Rather, they are cracks caused by weld discontinuities that created stress risers or reduced the effective area of the weld. These cracks typically occur while the weldment or structure is already in service. This will be discussed in more detail in the coming weeks when we discuss the importance of crack location for root cause determination.

Proper inspection after welding is very important to prevent a discontinuity from creating problems. However, it is more important to have proper welding and fabricating procedures that prevent or limit susceptibility to discontinuities and defects. And to reiterate, if you have a weld that cracks be sure to figure out why it did so you can prevent it from happening in the future.

References:

Fabricators’ and Erectors’ Guide to Steel Welded Construction

Please note: I reserve the right to delete comments that are offensive or off-topic.