Prequalified welding procedures are a great tool available to those who need qualified procedures in conformance with AWS D1.1 Structural Welding Code – Steel. However, there are strict requirements for the use of a prequalified welding procedures. It is not as easy as picking a qualified joint and using filler metal manufacturer’s recommended procedures. There are limitations in terms of material group, welding positions, bead thickness, maximum amperage, maximum electrode size and joint configurations as well as other limits. The Prequalification clause of AWS D1.1 clearly spells out these requirements.

The reason we have many different limitations and requirements is because when using a prequalified welding procedure we are not doing any testing. The testing has been done by others and the results have been verified. However, in order to have assurance of good results there are limits imposed to make sure manufactures don’t deviate from what is known to work.

All these requirements are not as stringent as you may image, but it is crucial to understand what they are. Once you have this figured out you can enjoy the advantages of using prequalified welding procedure.

Some of these advantages are:

- Time – eliminates or greatly reduces the time for procedure development as well as the time for testing procedures.

- Money – eliminates the cost of employees’ time in development and testing of welding procedures. It also eliminates the costs associated with destructive testing performed in-house or by third parties.

- Lower level of expertise required – Since you are not starting from scratch you don’t need to have expertise in procedure development to end up with a WPS.

- Quality assurance – If followed properly, the prequalified WPS provides reasonable assurance that sound welds will be produced.

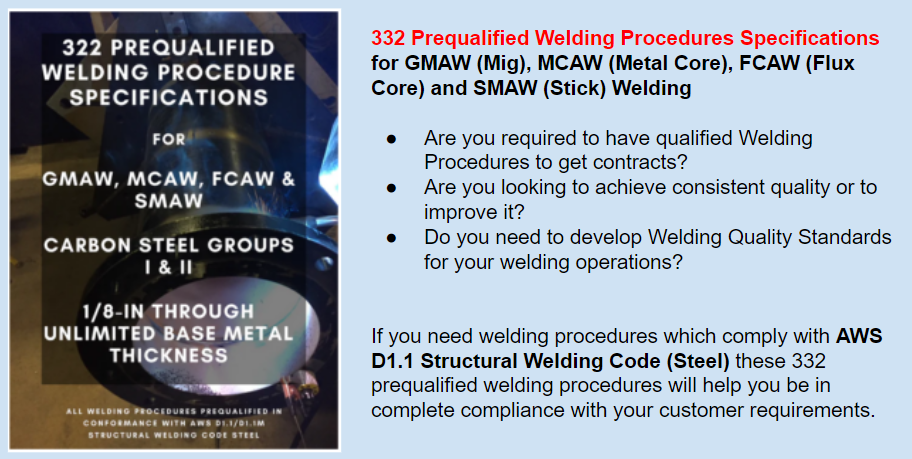

- Option to purchase – if you don’t have anyone in-house that can navigate Clause 5 of D1.1 (2020) or have the ability to assure compliance, you have the option of buying a prequalified welding procedure. Some companies have all the documentation ready for many different joint configurations, material types, welding processes, etc. They may also prepare the WPS for you if they don’t already have it. Be cautions with these services and make sure they provide full documentation other than just the WPS itself. They should spell out the limits of the WPS – such as maximum weld size in a single pass, maximum single pass layer width, etc.

We cannot emphasize enough the need to vet the source of prequalified welding procedures. Some of our customers have purchased prequalified welding procedures which, upon inspection, show critical violations to the requirements. One of the most common is using short-arc (short circuit metal transfer) in a prequalified procedure. This is NOT allowed. You can qualify short-arc by testing, but you don’t have the option to use it in a prequalified procedure.

The American Welding Society has Standard Welding Procedure Specifications (SWPS) available for sale. These SWPS have been developed by experts in the welding industry and qualified by extensive testing. These SPWS have accompanying PQRs showing test data. This is a great option if you are looking to outsource the development of a prequalified welding procedure.

There are certainly dangers in using prequalified welding procedures. You can take a look at some of these by reading Dangers of Using Prequalified Welding Procedures.

Do you want more information on how you can peform your own qualifications?

Do you want more information on how you can peform your own qualifications?

“Qualifying Welding Procedures, Welders and Welding Operators” is a guide developed to help you peform your own qualifications in full compliance to AWS D1.1 Structural Welding Code.

Am studying inspection level 1. So in order to pass easily. Tell the me tips

Hello Sipho. We have a lot of articles and resource that can help you including sample questions. Simply type “CWI” on the search bar of our website and you’ll see a list of articles that have information regarding topics you’ll see in the level 1 examination.

The link below will take you to an article in which you can download a free copy of sample welding inspector exam questions:

https://weldinganswers.com/how-hard-is-the-cwi-exam/

Been out of work for 4 years need to go back to school to many tempting agencies who know jack shit about this trade have to prove my self again

Good luck Andrew. Unfortunately there are only a few temp agencies that really do a good job at placing welders. Hopefully you can find work soon.

With fillet weld overlap

Hi, please recommend us SWPS by AWS

The required SWPS is for the following material

Process: SMAW

Base material spec: API 5L

Material No: 1 and group No: 2

ISO group: 11.1

Material type: X56 – Diameter 20 and above / Thickness 1 inch and above

Also give us a complete list of SWPS for sale that could cover other diameters and thickness for carbon steel materials

Thank you

Regards

Richard

Hi Richard,

It appears that the SWPS you need is B2.1-1-206. Please look at the description of the SWPS in the following range: B2.1-1-201 thru B2.1-1-206 and also B2.1-1-208.

These can be found and purchased through AWS by going to aws.org. On the top menu go to “Bookstore” and in the search box type: B2.1-1 and you’ll see the results. Make sure to read the description carefully to make sure you order the right one.

Hi,

In reference to material mentioned below and SWPS B.1-1-208 appears best please correct me

Base material spec: API 5L

Material No: 1 and group No: 2

Material type: X56

Regards

Richard

Hello Richard. Thanks for contacting us via email. It was a pleasure helping you out.

Thanks for sharing valuable information. Currently I just learning welding procedure & I would like learn more about Prequalified welding procedure.

I would like to learn more about welding , types of welding as I done practically mig and stick welding. And more on type of steel, stainless steel etc.