Voltage is one of the most important variables in a welding procedure. It is also one that is sometimes misunderstood. You may ask five welders what effect voltage has on a weld and you may get five different answers. This is because voltage can do a lot of things, some good and some bad. Understanding the effects of voltage on a weld is very important and can help troubleshoot welding issues quicker.

Voltage has a direct impact on heat input. As voltage goes up so does heat input. Heat input can be extremely important when welding materials whose physical and mechanical properties may be affected by it. In some cases we want high heat input to slow down the cooling rate and prevent embrittlement. In other cases we want low heat input to speed up the cooling rate and prevent sensitization cracking.

Many welders and other professionals in the welding industry will tell you that voltage controls penetration and that the higher the voltage the deeper the penetration. This isn’t accurate.

Voltage, when set in the correct range, has little effect on penetration. Within this range, the higher the voltage the lower the penetration. Yes, you read that correctly. Higher voltage decreases penetration. Yet many times we hear that to get deeper penetration you need to weld “hotter” and that usually means higher voltage. Higher voltage spreads the arc out and deposits a wider bead. Less energy density is exhibited as the voltage goes up, so penetration is decreased. Keep in mind that if the voltage is too low and you get an erratic arc you will start losing penetration as well. As stated above, we are discussing the effects of voltage when set within an appropriate range.

The main purpose of the voltage is to supply enough energy to arc to get adequate metal transfer whether in short circuit, globular or spray transfer. In a constant voltage welding process, mainly all wire processes, we set a voltage that the power source should maintain while welding. If our contact-tip-to-work distance increases our voltage theoretically should go up as the arc length increases, but the power source maintains the desired voltage by changing amperage.

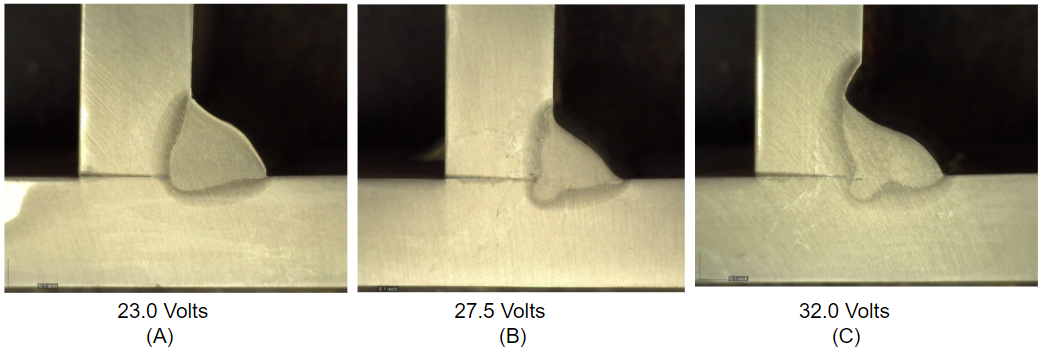

These welds were all made with .045” ER70S-6 wire, 90% Argon/10% Carbon Dioxide shielding gas at 375ipm wire feed speed. The only difference was the voltage.

As you can see, voltage has little effect on penetration. However, it significantly affects bead shape and penetration profile. When voltage is set low you will start getting excessive reinforcement in the weld. Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. If reinforcement gets excessive then the weld would fail the acceptance criteria of many codes, especially if the weld will be subjected to fatigue loading.

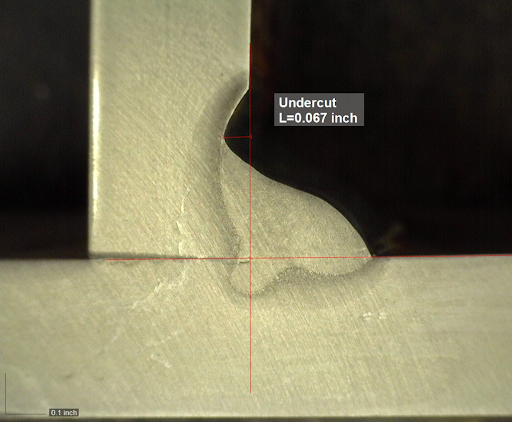

When voltage is set to high the weld puddle becomes very fluid and the weld may sag as can be seen in weld (C) above. When voltage is excessively high you can also get undercut. When undercut exceeds a certain depth it becomes a defect which must be repaired. Weld (C) also shows undercut on the vertical leg as shown below.

Excessive voltage may cause undercut as seen in this weld. The arc energy melts the base material but there is not enough filler metal to fill that void which then results in undercut. Undercut is dangerous as it can significantly reduce the fatigue life of a welded connection.

It is important to note that in constant current welding processes, such as SMAW and GTAW, the voltage varies based on the arc length maintained by the welder.

A welding procedure may have a wide range for voltage. This is common. But even a slight change in voltage may be enough to take you from globular transfer to spray. Or away from spray into globular. Setting voltage inadequately can have major costs implications as it can create rework by excessive spatter production, welding issues such as undercut, blow through and many more.

Thanks.