Tag Archives: AWS D1.1

How To Qualify A Welding Procedure

Whenever you hear that a welding procedure needs to be qualified it simply means that its suitability for use in a welded structure needs to be proven by testing. This means that the welding procedure must be capable of producing sound welds. But what are sound welds? Sound welds are welds that will perform in […]

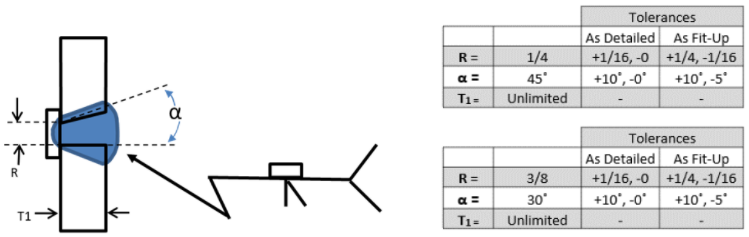

AWS D1.1 Prequalified Welding Procedures

Prequalified WPSs for GMAW, MCAW, SMAW, FCAW & FCAW-S

Prequalified welding procedures must adhere to the strict requiremnts of the welding codes which permit their use. AWS D1.1 Structural Welding Code (Steel) is one that allows their use. Prequalified WPSs are exempt from testing becasue there is reasonable assurance that as long as all the requirements are met the deposited weld will be sound […]

5 Questions and Answers You Must Know for the CWI Exam

And fundamental principles for the fabrication of steel structures

If you have taken or hope to take the CWI exam you probably have searched for some practice exam questions. In practicing for the code book portion of the test you may have come across a few questions for which you could find the answer, but didn’t really understand the importance of the question or […]

Why prequalified welding procedures are exempt from testing

One of the advantages of using prequalified welding procedures is that you can save a lot of time and money because they are exempt from testing. This means you don’t need to perform any destructive or nondestructive testing. You simply follow the requirements of AWS D1.1 and you can write a prequalified welding procedure and […]

The Relationship between Heat Input and Weld Size

Heat input is important because it has an effect on cooling rates which in turn can significantly affect the mechanical properties of the weld and heat affected zone. It also plays a role in susceptibility to distortion. High heat input can be beneficial in some cases and detrimental in others. A common misconception is that […]

9 Required Components of Welding Procedure Specifications

Regardless what position you hold, if you work in the welding industry you have heard of welding procedures specifications (WPSs). To some, a welding procedure simply means the selection of a few variables such as amps and volts. To others, these are the documents that govern all welding done in their facility. A […]

How to Weld Weathering (CORTEN) Steel

Corten, or COR-TEN, is the trademark name for weathering steels manufactured by U.S. Steel Corporation. Weathering steels are a family of low carbon steel alloys that were specifically developed to provide higher strength and more importantly eliminate the need to paint to protect against the elements (rain, snow, humidity, sun, salt, etc.). A242 and A588 […]

9 Changes for the New AWS D1.1 Structural Welding Code (Steel) 2020 Edition

The new edition of AWS D1.1 Structural Welding Code (Steel) has been released. If you are looking to get the hard copy you may need to wait a few weeks, but the electronic version is ready for purchase from the American Welding Society (AWS) through their website. There is a significant cost to obtain the […]

The 9 Clauses of AWS D1.1 Structural Welding Code Explained

The most widely used welding code in North America, and perhaps the world, is AWS D1.1/D1.1M Structural Welding Code – Steel. It is specified as the quality standard in hundreds of contract documents every year. Yet, we find that less than half of the fabricators that need to use it have a sound understanding of […]