One of the advantages of using prequalified welding procedures is that you can save a lot of time and money because they are exempt from testing. This means you don’t need to perform any destructive or nondestructive testing. You simply follow the requirements of AWS D1.1 and you can write a prequalified welding procedure and use it in production in a matter of a couple of hours.

But if welding procedures are such an important component when it comes to assuring quality, why are prequalified welding procedures so trusted? The answer to this question is that following all the requirements of the code for prequalified WPSs provides reasonable assurance that the WPS can produce sound welds. The requirements are pretty stringent and prohibit a large number of scenarios where quality may be compromised.

Below are just a few of the items prohibited by AWS D1.1 when considering prequalified WPSs.

- GMAW Short Circuit Transfer (GMAW-S) – since short circuit (short arc) is a very low heat input process it is probable that it will result in lack of fusion, especially in thicker sections.

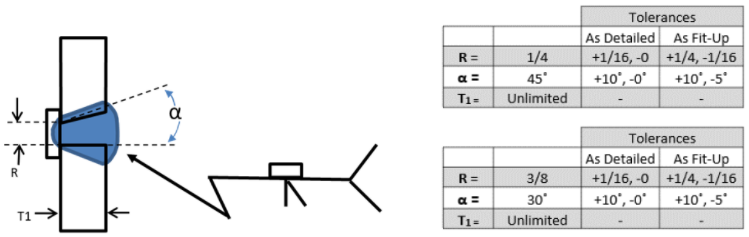

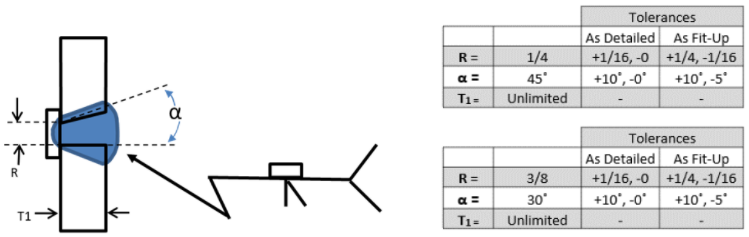

- Narrow groove angles – The smaller the included angle the less weld metal is needed, and thus the lower the cost per foot of weld. However, narrow grooves make the weld susceptible to a lack of root fusion. Similar to not allowing GMAW-S, not allowing narrow grooves aims at reducing lack of fusion.

Prequalified joints provide values for groove angles and allowed deviations (tolerances). Tolerances allow for wider groove angles but not narrower. To get a narrower angle the root opening must be increased .

- Eliminating preheat for certain base metal thicknesses – preheating is used to slow down the cooling rate of the weld and heat affected zone. It is possible to get enough heat input from the welding process to avoid a cooling rate that is slow enough to avoid susceptibility to hydrogen induced cracking, but this is something that should be qualified by testing.

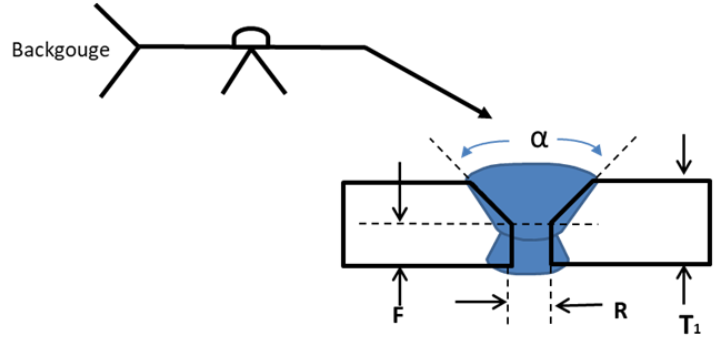

- No double-sided CJP welds without backgouging – backgouging allows us to see how deep we penetrated with the first pass, it opens up the groove for the second pass, gets rid of narrow grooves at the toes of the root of the first weld and it gets rid of any trapped slag if using a welding process such as SMAW (Stick) or FCAW (Flux-core Arc Welding).

Complete Joint Penetration joints with no backing require backgouging. This requirement cannot be waived for the procedure to maintain its prequalified status.

- Fillet weld sizes smaller than those permitted by Table 7.7 of AWS D1.1 (2020) – fillet welds that are too small for a given base metal thickness make the weld and heat affected zone susceptible for being excessively hardened.

- Fillet welds sizes larger than those permitted by Table 5.1 of AWS D1.1 (2020) – fillet welds of excessive size for a given welding process and welding position can create welding discontinuities such as overlap and lack of fusion.

- Using base metals not listed in Table 5.3 of AWS D1.1 (2020) – certain base metals, even some that conform to the scope of the code in terms of thickness and minimum specified tensile strength, may present certain risks that should be avoided. If the base metal you are trying to qualify is not listed in Table 5.3, the welding procedure cannot be prequalified and must be qualified by testing in accordance with Clause 6 (Qualification) of the structural welding code.

As you can see there is rhyme and reason to all the requirements and limitations imposed by the code when prequalifying a welding procedure. If you follow these instructions you will end up with a welding procedure that will produce sound welds.

It is important to note that we still depend on the welder to deposit the weld. This is why, regardless of whether we are using a welding procedure qualified by testing, or a prequalified one, the welder must have proven ability to use such procedure and produce acceptable welds. This is verified by welder performance qualification tests.

References:

AWS D1.1/D1.1M:2020 Structural Welding Code – Steel

How to Use, Develop and Revise Prequalified Welding Procedure Specifications

332 Prequalified Welding Procedure Specifications for Steel Fabricators

Do you need qualified welding procedures to get control of your welding quality and productivity? Are you a CWI looking to have a library of welding procedures? Do you need documented welding procedures to satisfy customer requirements? If so, this new resources may be just what you need.

Click here to learn more about this special offer.