Tag Archives: prequalified welding procedure

Understanding the Difference between Qualified and Prequalified Welding Procedures

One of the most common questions we get around the topic of welding procedure qualification is regarding the differences between qualified and prequalified welding procedures. The main question is typically: is one better than the other? Before we answer this question, let’s first discuss the need for qualified, or prequalified, welding procedures. If you have […]

Pick Your Prequalified Welding Procedures Carefully

If you work with AWS D1.1 you are probably familiar with the use of prequalified welding procedures. The use of prequalified WPSs provides many benefits to the fabricator, one of which is costs savings due being exempt from having to perform costly testing to qualify the welding procedure. However, if you are looking to save […]

How To Qualify A Welding Procedure

Whenever you hear that a welding procedure needs to be qualified it simply means that its suitability for use in a welded structure needs to be proven by testing. This means that the welding procedure must be capable of producing sound welds. But what are sound welds? Sound welds are welds that will perform in […]

How to get a Qualified Welding Procedure Quickly

Have you ever been in a situation in which you need a qualified welding procedure immediately? Maybe you just failed an audit and have to halt production until a valid welding procedure is provided. Or maybe you’re just in a hurry to get started with a new job. Regardless of the reason you need the […]

5 Questions and Answers You Must Know for the CWI Exam

And fundamental principles for the fabrication of steel structures

If you have taken or hope to take the CWI exam you probably have searched for some practice exam questions. In practicing for the code book portion of the test you may have come across a few questions for which you could find the answer, but didn’t really understand the importance of the question or […]

5 Common Mistakes Made When Estimating Welding Costs

Read this before you bid on a welding contract

When bidding jobs several fabricators end up calculating their costs associated with welding and then double that number to be safe. In some cases, that isn’t even enough. It is important to have a clear understating of how to translate the amount of welding to be done to actual manufacturing costs. One of the biggest challenges is that rework and overwelding is […]

21 Changes to PQR Essential Variables that Require WPS Requalification

Have you ever seen a welding procedure specification with established amperage ranging from 200 to 550 amps? Or voltage ranging from 21 to 29 volts? Or some other variable with a huge window? This is all too common, but extremely dangerous. Why? Because changes to essential variables beyond that which is reasonable will affect the […]

What is a Qualified Welding Procedure?

A qualified welding procedure is a welding procedure that has been proven to produce sound welds after undergoing extensive testing. When using structural welding codes, these tests include both destructive and nondestructive tests. Some of these tests are: Visual examination Macroetch Break test Bend test Ultrasonic inspection Radiographic inspection Hardness test Tensile test The reason […]

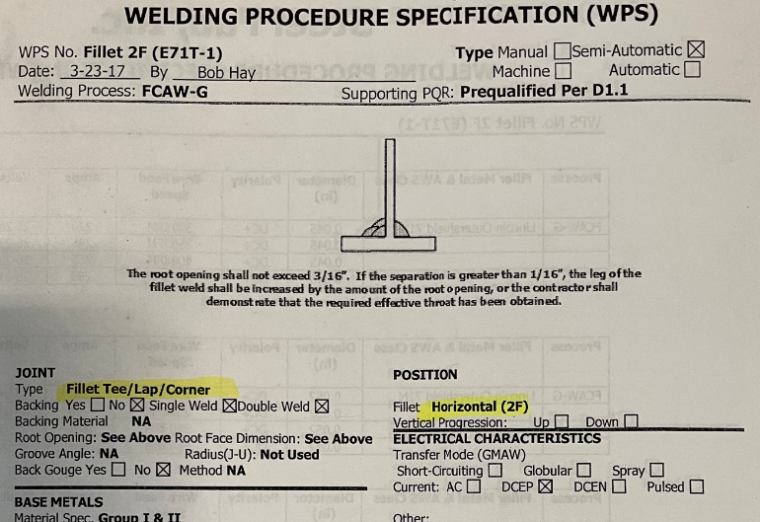

Frequently Asked Questions about Prequalified Welding Procedures

The following FAQ are related to 322 Prequalified Welding Procedure Specifications for Steel Fabricators. To learn more or to get your copy simply click here Is this a physical book? No. The procedures are provided as digital files (PDF) and are available for immediate download. The user has the option to print the files […]