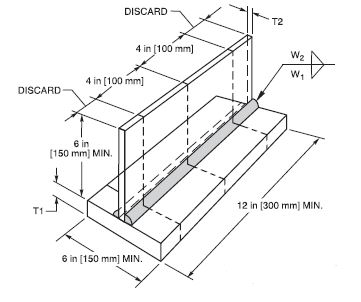

The AWS D1.1 1G Welder Qualification Test

The AWS D1.1 Structural Welding Code (Steel) welder qualification plate tests consists of a groove weld with a 45-degree included angle. The plates are prepared to a knife’s edge and a ¼ in [6 mm] backing strip is used. The test for unlimited thickness will use plates that are 1 in [25 mm] thick. Anything […]