Tag Archives: weld strength

Which Welding Process Produces the Strongest Welds

SMAW, GTAW, GMAW, FCAW, MCAW or SAW?

How Carbon Content Affects the Weldability of Steels

And its effects on strength, hardness, ductility and machinability

Steel is an alloy of iron and carbon along with several other elements in small quantities, all of which have an impact on its properties. Steels can contain varying amounts of carbon and are typically categorized as low, medium or high carbon steels. Low carbon steels are those containing 0.30% carbon or less. Medium carbon […]

The Advantage of Using Undermatching Filler Metals on High Strength Steels

High strength steels are becoming more and more popular in steel construction. Higher strength means we can reduce the thickness of the base material and thus reduce weight. This is very important not just in vehicles but in static structures as well. However, higher strength steels usually bring about a few issues that if not […]

The Outrageous Cost of Poor Fit Up in Welding Operations

You will cringe when you read this

In a perfect world parts would fit together perfectly every time. However, as we all know, this isn’t the case. We mostly think of poor fit up as something that annoys welders but which they can compensate for. But the reality is it can have tremendous impact on your bottom line. Or, in many cases, […]

Is Weld Strength Affected by Shielding Gas Mix?

Can our selection of shielding gas affect the strength of a weld and other important mechanical properties? Absolutely! The difference is more pronounced when using flux-cored (FCAW) wires than when using mig (GMAW) wires, especially as the wire’s tensile strength goes up. Although we can affect strength by using different gases, what we should be […]

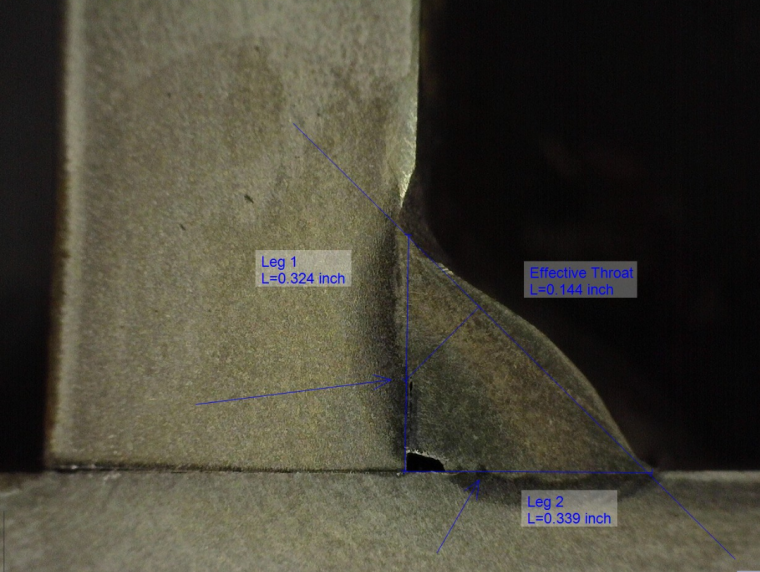

Importance of Macro Etch Testing of Welds

Macro etch tests are commonly done as part of qualification tests for welders and welding procedures. This test is relatively easy to do and does not require complex or expensive equipment. However, very few fabricators ever perform this test. A macro etch test can serve as verification that a change on how something is welded […]

Bigger (Weld) Is Not Always Better

When it comes to fillet welds, bigger is not always better. A fillet weld is easy to measure, simply take out your fillet weld gauges and measure it. However, there is an incorrect assumption that a bigger weld (as measured with a fillet gauge) is always stronger than a smaller weld. Before we get into […]

6 Mistakes That Can Lead to Cracked Welds

Cracks on welds are never good. Welding codes always have allowances for porosity, undercut, weld sizes, and even weld profiles. However, there is never an allowance for cracks. Being a linear discontinuity, a crack will tend to propagate through the weld and into the base metal with relative ease, especially in cyclically loaded structures. So […]

How to Determine the Shear Strength of a Fillet Weld

In our previous post we explained how to determine the strength of a transverse fillet weld. A transverse fillet weld is one that is perpendicular to an applied load. We will now look at how to determine the strength of a fillet weld under shear stress. If the load applied is not perfectly perpendicular to […]