How to Calculate Deposition Rate for Solid Wires

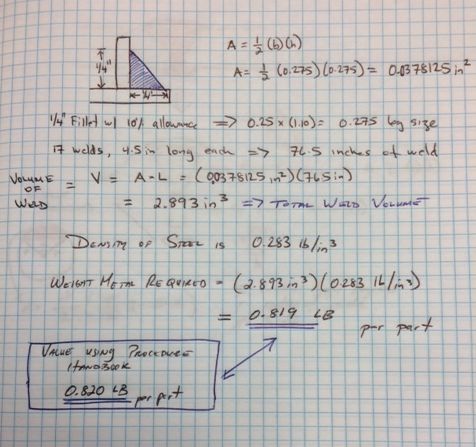

A common question that is asked when manufacturers are trying to determine costs associated with welding is: How many pounds of wire can I deposit per hour? Or, how many pounds of wire can I deposit at a specific amperage or wire feed speed? There are charts to help you determine this, but it’s always […]