Hydrogen-induced cracking (HIC) is a far too common type of failure. It is also called hydrogen assisted cracking (HAC) and delayed cracking since it does not occur right after welding, but a few hours or days after the weld has completely cooled down to ambient temperature. Cracking occurs due to a significant loss in ductility […]

Normally the posts on our blog are inspired by questions frequently asked by customers. Unfortunately, the question above is not asked that often, but it should be. A welding procedure specification (WPS) is a set of instructions that if followed to the letter, insure a sound weld. A WPS will typically provide ranges rather than […]

Have you ever wondered, or have you ever been asked how many inches of wire are in one pound of filler metal? You may have been asked something like: “How many inches of wire are there in a 25LB spool of .035” ER70S-6 mig wire?” Typically, this questions is asked when someone is trying to […]

Reading welding symbols is very important at several levels of an organization. A welder needs to be able to interpret welding symbols to insure he puts down the right kind of weld, that he prepares the joint properly, that he places the weld in the right spot, right sequence, right dimension, etc. A design engineer […]

Let’s keep it simple. 4140 steel can be welded without problems as long as you follow some simple guidelines. This also applies to AISI 4140 and 4340. We will not be discussing the metallurgical properties of 4140 or trying to explain what happens to its microstructure when it cools too rapidly, just remember that the […]

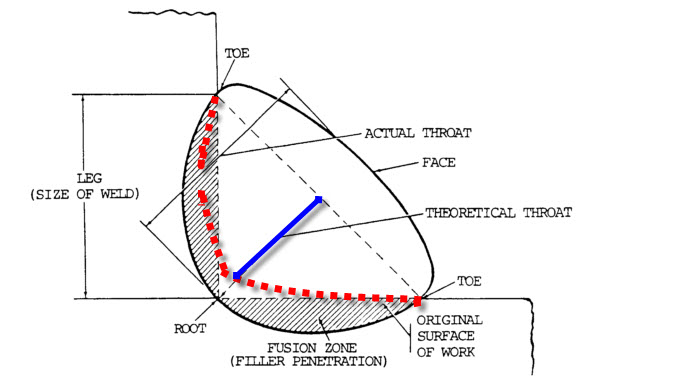

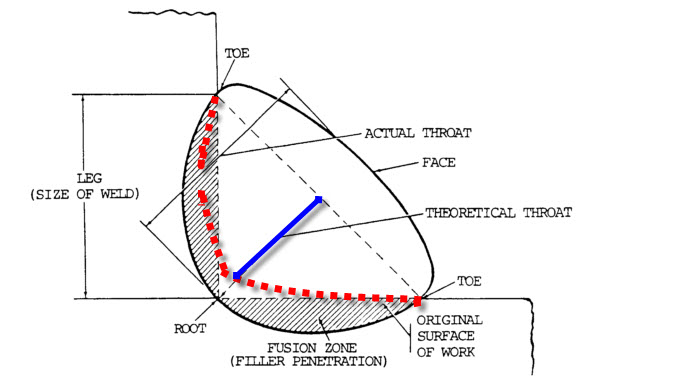

When weld sizes are determined by design engineers, the theoretical throat is used to calculate weld strength which in turn gives our leg size (for fillet welds). This means that the desired strength of a weld is achieved only if we attain fusion to the root and side walls. The terms fusion and penetration are used […]

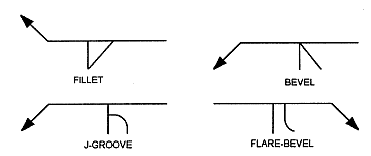

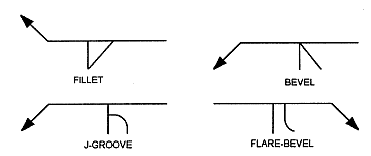

Welding joints vary widely but can be traced back to a few basic joint types. Typically we hear terms like fillet weld, butt weld, lap weld or corner weld. These are all all joints but within these there are variations. Below we outline the joints and provide a graphical representation. These joint types are categorized […]

What alloy is used to weld stainless steel to carbon steel?

This is one of the most frequent questions we receive. If you are welding mild steel to stainless the recommended alloy is 309L or 309Lsi. This is true even if the stainless base material is 304, 308 or even 316.

For joining stainless to mild steel use a 309L filler

A not so common question is whether carbon steel can be welded with 308L. There are a few reasons why you would want to weld carbon steel with a stainless filler, most of them have to do with not having to change out the wire in robotic applications for short runs of mild steel product. It makes sense that 308 would be sufficient, but this is not always the case. A 308 filler would yield a deposit that when mixed with carbon steel would be similar to a 410 stainless deposit. This would be a weld deposit that may be too brittle for the application. The recommended filler in this case would also be 309L since when mixed with carbon steel it yields a deposit similar to a 308L deposit.

For more information on welding stainless steels you can read 5 Common Mistakes Made Welding Stainless Steel.

A common question in the field is which wire type will provide the best deposition rate. In one of our earlier posts “Calculating Deposition Rate for Solid Wires” we discussed deposition rates strictly for solid wires. Here we will talk about deposition rates across wire types – mainly solid wire, metal-cored wire and flux-cored wire. […]

Even for those of us dealing with welding all day every day it is difficult to remember the welding position nomenclature. So here is a quick cheat sheet. Fillet Weld Positions Groove Weld Positions Pipe Weld Positions Which do you consider to be the most challenging welding position?